-

• #177

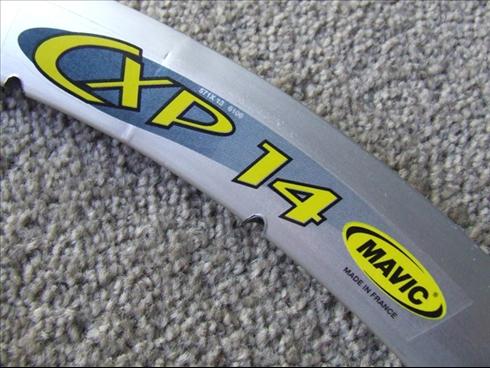

cxp 30 and cxp 14 dont have it

-

• #178

open pro's do

-

• #179

just checked an open pro, theres a little sticker with tyre min/max width info completely covering the gap

-

• #180

Don't know about the CXP 30 but the CXP 14 just had the weld left visible (possibly sanded down by hand a bit) which I think is uglier.

It's mostly aesthetics, but I bet you could feel that ^ weld under braking.

-

• #181

And yeah, Open Pros have the same machining hidden under a sticker.

-

• #182

I've recentrly bought a pair of Dodici rims.

http://www.lfgss.com/thread83699.htmlKnowning nothing about the wheelbuilding , I need an advice on choice of hubs.

I've read that Phil Woods are the best (but way over my budget). And 2nd choice would be goldtec which are quite expensive as well.

So, I did some search and found those 2 hub sets. And I need your advice which are better...Dia Compe Gran [Black] 32h - £80 (Just hubs)

Token [Black] 32h - 62£ (Supplied with alloy 16T sprocket, lockring and nuts)

Or maybe you can suggest something else? And I want it fixed gear. -

• #183

dia compe track hubs are made by formula, they have upgraded axles and nuts. token are made by novatec, pretty much the same version as used by other brands.

http://www.planet-x-bikes.co.uk/i/q/HUOOLF/on_one_large_flangetrack_hubhttp://www.planet-x-bikes.co.uk/i/q/HUPXPITR/planet_x_pista_track_hub

-

• #184

Once you get down to that level, you might as well just buy the Joytech/Novatec hubs from whoever has them at the best price on the day. Planet X have them at £19.99 each, so about £55 for two hubs, sprocket and lock ring. If you look closely, you can see that Token have very sensibly subcontracted their hub production to the specialists at Joy Industrial Co. Ltd just like everybody else. If you are a Wiggle Platinum customer and have a voucher code, I think you could save 10/- compared with On-One, but you'd have to wait for them.

-

• #185

I had Joytech hubs on my previous bike. Weren't great but not so bad either. I'm looking for something of a better quality/level.

So, would you recommend to spend a bit more and get Dia Compe ?

-

• #186

joytec also make loose ball bearing track hubs under their own name, maybe thats what you had.

-

• #187

Sounds plausible; Joy tend to use the Joytech brand for very low end OEM stuff and Novatec for their better kit.

NB: Joytech has an H, Novatec doesn't.

-

• #188

So, would you recommend to spend a bit more and get Dia Compe ?

DiaCompe aren't actually better than Novatec, they just have hipster tax added because they are a Japanese brand rather than a Taiwanese one.

-

• #189

DiaCompe aren't actually better than Novatec, they just have hipster tax added because they are a Japanese brand rather than a Taiwanese one.

That's all I needed to hear :) thank you sir.

-

• #191

I am in East London and I have used Arup before also, didn't know he had moved South. There used to be guys here who did workshops - does that still happen? I have a set of solid wheels with steel rims that I would like to true. I have never tried to true wheels before only ever semi-build ie the lacing of the spokes etc.

If anyone could assist for some beers or bottles of wine give me a shout.

-

• #192

how much truing can you actually do on a steel rim ??

-

• #193

Quite a bit, as it turns out. They usually have lots of spokes, and are often made from thin sections which lend themselves to being pulled around, particularly in the radial dimension.

-

• #194

I'm going to be building a wheelset shortly using DT Swiss Revolution spokes. They're 14/17g butted which is thinner than I've used before (only built with plain gauge or 14/15g).

I've read that can be tricky to build with due to excessive wind-up. Can anybody confirm if that is the case? I'm assuming that if I'm thorough with stress relieving every time I tension I shouldn't have much of a problem?

-

• #195

Yes, they wind up, and it's not stress relieving you need (that sorts out bending of the spokes at the ends) it's unwinding. You turn the nipples back a bit after tightening to undo the torsional stress on the spoke. There are various tricks to it, but doing it by feel works as well as any of them. Keep one finger of your nipple driver hand on the spoke with and you can feel the relative movement. If the spoke is turning with the nipple, it's either winding up or unwinding.

Loads of wheels have been built with Revs, so it's clearly not impossible.

-

• #196

Thanks for the info

I've seen the trick of putting bits of tape on the spokes to see the wind up but will be much more valuable to learn to do it by feel.

-

• #197

^ spoke 'flags' work well IME as you can tell exactly how far the spoke has twisted and where it stops twisting and you're actually putting tension into the spoke.

I built a set of wheels with Revs on CXP 33 and they didn't wind up any more than usual, somehow - a quarter turn of twist & untwist.

And they haven't made a sound on the road so I guess there wasn't any residual twist left.

Just make sure you lube the threads and the nipple seats properly.

-

• #198

Cheers. I've never used flags before as I've never had any issues with wind up. I've always backed spokes off slightly after tightening but just being a bit more cautious this time!

What did you use as flags? I was thinking of a cm or two of insulating tape would work OK

-

• #199

I used them f & r(nds) with some 32h Excellights, mainly using the backing off trick with the spoke key (just go 1/8 turn beyond, then back). I also think they need a little more tension than Comps or equivalent, in order to stay in true more readily.

For stress relief, you can just have a wank between wheels.

-

• #200

For stress relief, you can just have a wank between wheels.

Wouldn't that stress the wheels even more? I can't imagine they'd enjoy watching

dicki

dicki Regal

Regal gbj_tester

gbj_tester upstart

upstart BringMeMyFix

BringMeMyFix

I'm pretty sure most welded rims will have the excess CNC-d off like that. Not sure they could get it to be invisible without hand finishing it at prohibitive cost. The CXP22 is pinned if you prefer that look.