-

• #477

-

• #478

What causes spokes to fail at the nipple with the break occurring right at the bottom of the threads?

This is my second factory built set of wheels with same "issue" (hello Powertap); the two sets I've had handbuilt from scratch have been bomb-proof but I snapped a NDS spoke on these disc 29er Charge stock wheels last night

I replaced the spoke at 6am this morning, retensioning + trued with Park TS-2 + tensiometer (tension was all over the place) and then on way home tonight poing goes a DS spoke exactly the same way.

-

• #479

Spoke bracing angle might be too extreme. Sapim nipples are better than DT Swiss as they can sit in the spoke holes better.

-

• #480

The number of spokes and your own weight effects it too

-

• #482

I'm a big fat fucker and they are 32h on a 60mm/52mm asymmetric Formula generic disc hub but rims are shallowish and eyletted. The Powertap was on A23 rims and the combo of super large flanges and non-eyeletted rims was a horror story

edit oh Charge you have spoiled me with plain guage spokes and 14mm nips even though rim doesn't need them, I should have paid some attention. :(

-

• #483

Failure to stress relieve properly is a candidate cause for fatigue failures at the threads.

-

• #484

Sorry I haven't been able to read through the full ten pages yet, but wondered if anyone can help with a spoke length dilemma.

I've got a Ventura coaster brake hub which I want to build to an old Van Schothurst 26" mtb rim off an ageing Raleigh Alaska for pubtasticness, however neither of these can I find any info for on spocalc.

It seems it wants pretty serious sub-mm measurements. Any ideas how I can work out appropriate spoke length?

-

• #485

Measure it?

-

• #486

^^ You only need a few of the measurements, will try summarise at some point, but think it's earlier in thread or in a simpler calculator online.

Meanwhile, anyone know the ERD for the Jalco drx6000's you persuaded me to buy? ;)

-

• #487

Erd.... Is there a way to measure it without doing this?

Looking to build a set of American Classic track hubs to some 38mm carbon rims, not sure of the manufacturer though, they have a very slight offset...

-

• #488

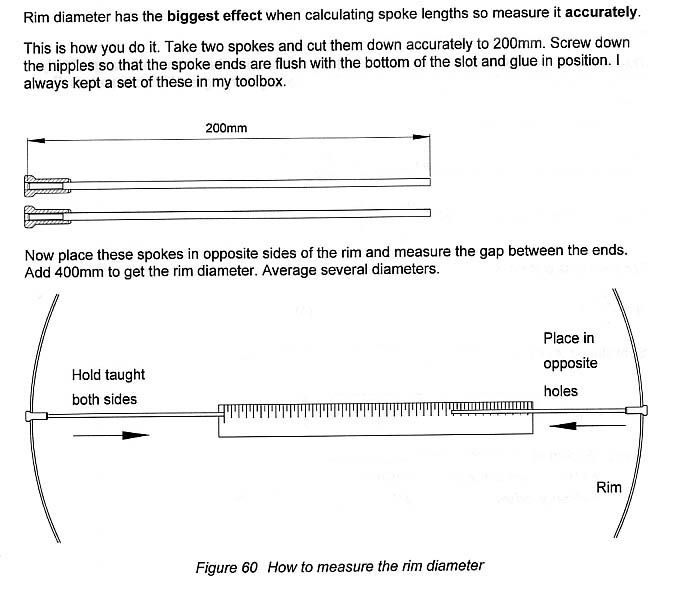

How to measure a hub and rim

-

• #489

Was hoping there'd be an easier way, don't think my tape measure is that accurate.

-

• #490

You can do it with the depth guage of your vernier caliper, use the outer diameter of the rim as a datum then take depth soundings to the bead seat and the spoke bed. Since the bead seat is a known diameter (622mm for 700c), the rest is simple arithmetic. This method doesn't need to account for non-circularity of unbuilt rims, and the errors will be part of small measurement; where 1% error on a full rim diameter measurement will be wrong by enough to make the wheel unbuildable, 2% on the 10-30mm depth measurements will be of the same order as the granularity of spoke supply.

-

• #491

^ does that translate to a simple formula?

-

• #492

Yes, you have 3 numbers, known bead seat diameter (BSD) & your two depth soundings A=depth to bead seat B=depth to spoke bed.

ERD + 2B = BSD + 2A = overall diameter of rim

-

• #493

is it safe to buy a new rim and build it up using these spokes? or are they likely to be somehow buggered. some are a bit bent but none too badly. Also, the way the rim has broken at the pin, is this normal or does it mean the rim is shit?

-

• #494

How did that occur?

I'd lead towards re-using the spokes and nipples unless they've already had a long hard life. But if you're facing the hassle and delay of buying a new rim, it's not much more time and money to buy new spokes too.

A page ago i was speculating about failures at rim joints. Pinned joints are common practice, but if you don't believe my theory you might want to seek out a rim with a welded joint.

-

• #495

I've reused spokes from a wheel more pringled than that, did many miles and not had a failure. Just inspect them all. I ended up binning 2 spokes and the rest were fine

-

• #496

Did On-One ever actually produce their 29er clincher carbon rims?

-

• #497

I was looking to build up a fixed/fixed wheel for track and commuting. Other than the System EX ones should i be considering any others? There doesn't seem to be choice out there. The Halo ones seem pricey in comparison. Is the quality that much better?

-

• #498

They are all the same basic hub, Planet X seem to be cheapest for UK.

-

• #499

FWIW I like my PX / On one's.

Cheap, simple looking, replaceable cartridge bearings. What more could you want.

-

• #500

Yes, you have 3 numbers, known bead seat diameter (BSD) & your two depth soundings A=depth to bead seat B=depth to spoke bed.

ERD + 2B = BSD + 2A = overall diameter of rim

Thanks for that. Do you always round down? If so it looks like I need 20 290 and 24 284 cx ray...

gbj_tester

gbj_tester dubtap

dubtap Regal

Regal Jezston

Jezston chisa

chisa rhb

rhb Dandy

Dandy Borek

Borek moth

moth Hovis

Hovis malandro

malandro hugo7

hugo7

Ah, that makes sense. Ta.