-

• #27

I did some digging at work around that, I've got both printing and single crystal casting (we have the ability to print one off forms to form a casting shell) facilities available to me. For both the costs are astronomical and I think it'd be wise to avoid pissing the production line managers with my own projects.

-

• #28

Did a little bit more today, not too sure about the headtube shape as whilst it is ideal for welding/brazing the swan neck join for the spine to it looks quite shit being all uneven. Also the extra metal needed for a nice shallow taper adds a lot of weight, so I think I'm going to turn another tube in the same two even step style as the other but with a much larger step down to the centre section to cut weight down a bit.

Not very good at documenting the process which I'm sure would be more interesting than just finished pictures, must improve on this.

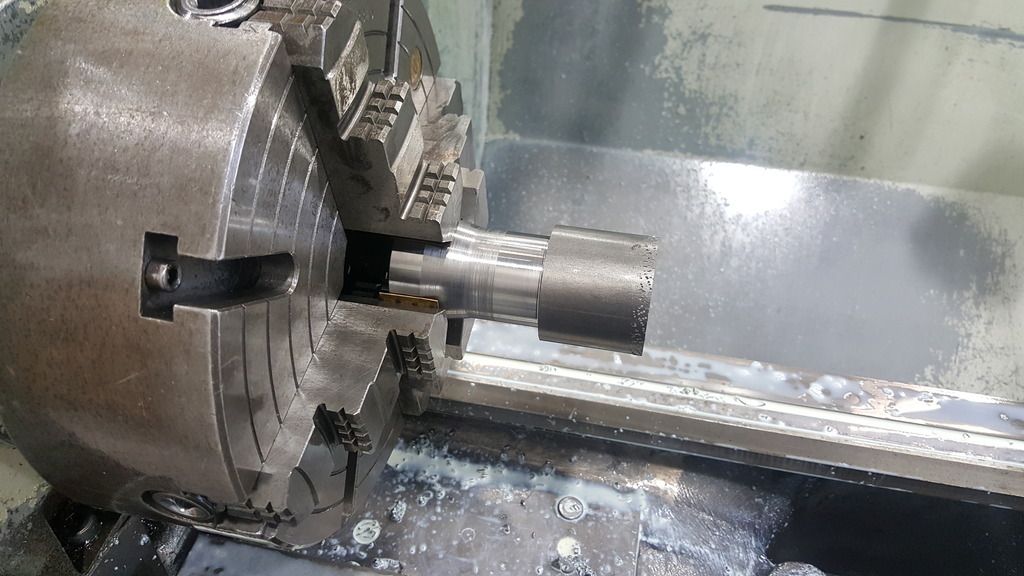

Turning second bearing seat/external features:

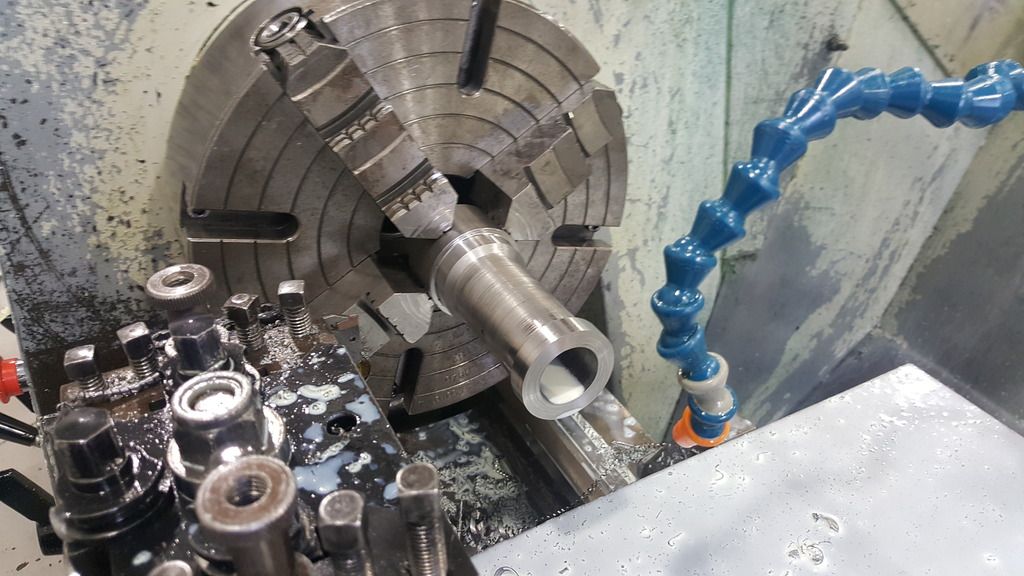

One finished headtube:

Set out all headset bits to measure and check:

And an 'assembled things' picture, need a lower sitting bearing cover:

Silver lining is that bearing seats are spot on for the integrated headset!

Next up:

-source some forks to chop up for the rear wheel

-mill the crown plates, press and weld/braze them onto the steerer and machine top face for crown race seat

-source some tubing for the fork legs

-try and find a tapered tube long enough for the spine -

• #29

Not got much done this week as work was a bit hectic a load of senior managers getting 'moved on' and my business sector getting merged with another...

Despite it being adequate, I really didn't like the first integrated bearing headtube I made, so had another crack at it early in the week:

Changed the way I was machining, got all features done to then part-off and be left with just the lower bearing seat to machine in a collet chuck so it was concentric:

Also got to play with the proper tooling for the critical dimensions:

= one finished headtube that I like (other than the crap finish in the centre but that'll be brazed/welded to anyway)

Also went for a forum favourite and matched a 'slam that stem' cover to the headtube:

To make a completed unit I'm actually happy with:

And i now have tubing on order:

-3m x 40mm OD 2.0mm wall thickness for the spine

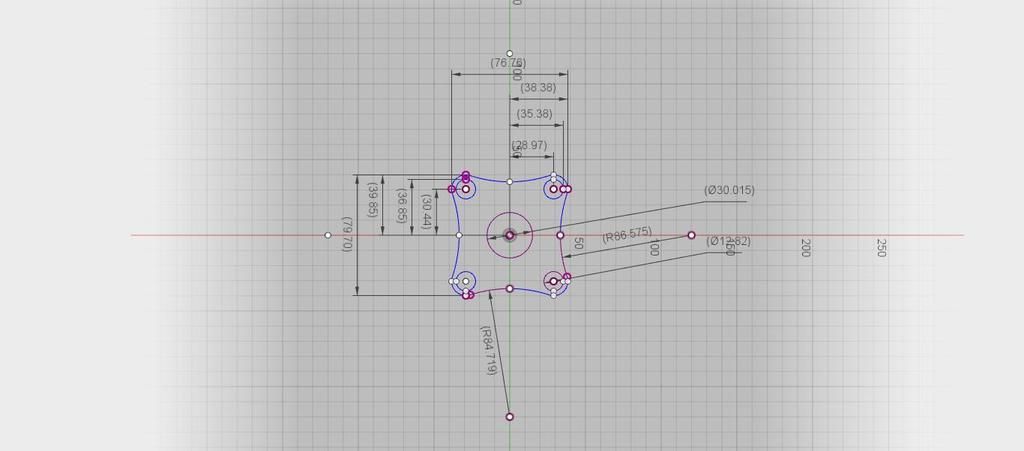

-3m x 1/2" OD 1.6mm wall thickness for fork legsAlso i drew up some fork crown plates, got them programmed into the CNC mill to be done next week now:

Was going to get the spine formed and order the wheel this weekend but forgot I was riding Mountain Mayhem, so I'll have more information as soon as I get cracking again

-

• #30

Too cool for school. Loving this thread!

-

• #31

I want that machine! Looks like you can tunnel to France and make black holes and everything.

-

• #32

How is this going?

-

• #33

Have you seen the four-tubed fork legs @superted Ted James has been building recently? Might be of interest to you, there's some recent pics on his Insta of them.

I'm intrigued what tyres you'll end up with. Could you contact a tyre co's about making custom size? Perhaps solid rubber, there's a newish version of solid tyres out there, I've seen them on the road and in mags.

-

• #34

Final headtube looks The Nuts by the way!

-

• #35

Apologies for the lack of updates on this, I've been shifted to design office/testing at work now, and it was sooner than expected so getting stuff done at work became impossible.

@drøn hopefully the fork crown plates will be machined next week, they are programmed into a 2 axis mill and i just need a couple of hours free to run down to the workshop and get them done, if not I'm going to bore the tight steerer tolerance out of two plates, then mark, drill and file the fork leg holes on a pillar drill (1" fork legs).

The forks are the crux of the project, as once they are confirmed and together I can get working on spine radius/length

@Skülly thanks! I'll have a look at what Ted's doing, I'm open to any ideas as I'm fairly clueless, but I like building things that are completely impractical and dangerous....

On the tyre front, I'm going to try and get an uncut length of solid tyre from someone that makes them, but that's going to be a problem I'll worry about later on.

I do have pictures of something I've been playing with recently, unfortunately it's not for my build but I'm sure will be of interest, will upload later today.

-

• #36

Update plz!

russmeyer

russmeyer drøn

drøn Skülly

Skülly Scilly.Suffolk

Scilly.Suffolk

Tagging @kat for penny fun :)