-

• #2

A colleague built an 'ordinary' some years ago - the biggest problems were the front tyre (making one, then getting it to stay on the rim) followed by issues with rolling the rim. Unless you've already got something, I'd start with the front wheel before getting too far into machining parts...

-

• #3

Subbed.

Just my kind of project! good luck and have fun. -

• #4

Luckily I've got a source for a wheel, was looking at rolling some blank box section but at the risk of it folding I'd rather trust that to someone else.

Just need to wait until next payday and I'll have the rim to start mocking up forming the spine radius -

• #5

Sounds fun - looking forward to pics of it as it develops.

-

• #6

Subbed, good luck! Haha

-

• #7

What sort of tyres do these actually use?

-

• #8

Large ones? Maybe.

-

• #9

Marathon ++++++++++++++++++++'s.

You don't want to be changing it too often! -

• #11

Sounds good

-

• #12

Tyres are solid rubber, cut a length about 1" short of wrapping around the rim and put a metal corkscrew type insert into one end, then twist the other and wind it onto the 'screw'. Leaves a tight fitting band of rubber (I hope).

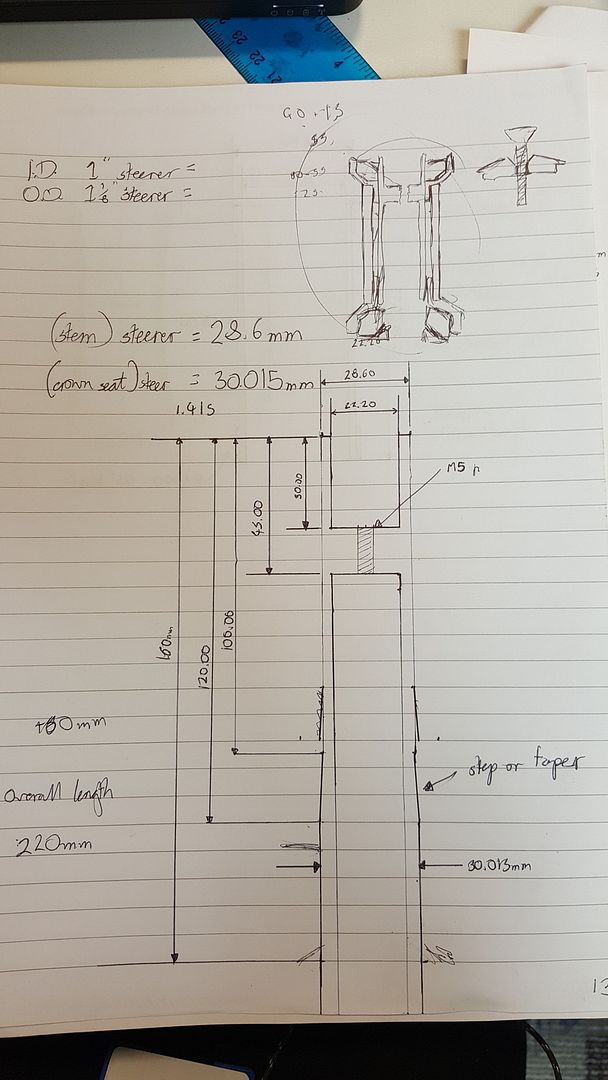

Been playing with a lathe today, I drew out the headtube and steerer I wanted when I was bored on Monday, got the headtube finished and steerer is half finished.

Couple of drawings:

First steerer won't have threaded portion, internal steerer diameter is that of a 1" steerer so I can use a star nut

28.60 Steerer portion with taper

Rotated in chuck ready for 30.015mm crown race fitting portion of steerer to be turned

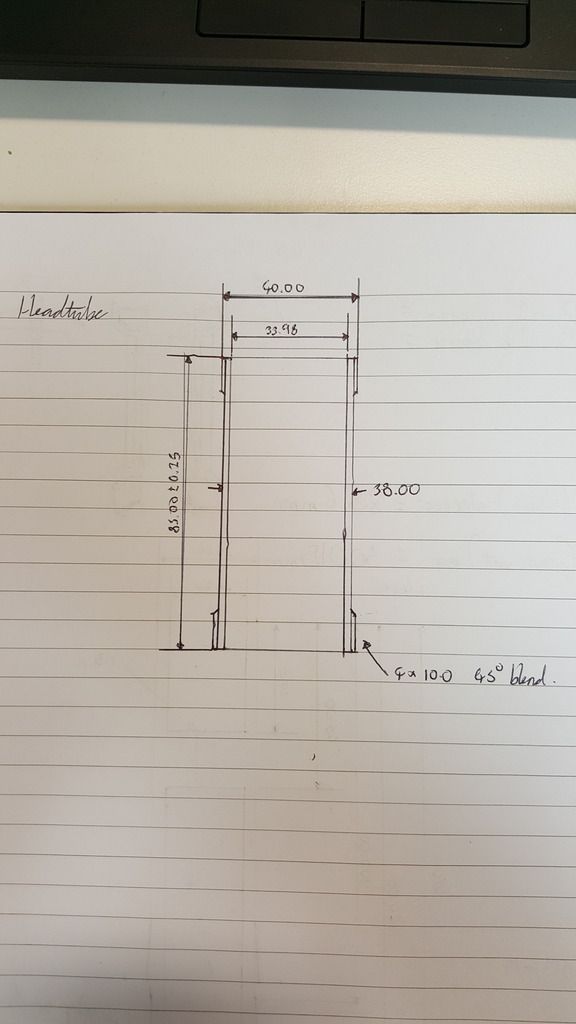

Headtube for External Headset

Couldn't figure out why the surface finish was crap until my tool cracked and shattered on the finishing cut...

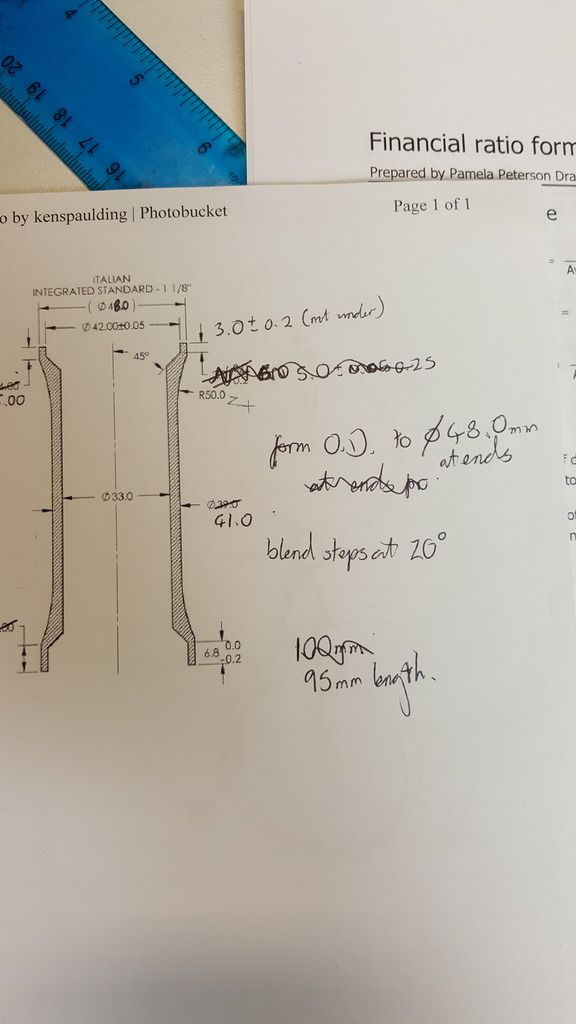

And finally a drawing for an internal headset headtube that uses BMX style bearings, I will not be producing the external taper just uniform with two steps at the bearing seats

-

• #13

Not sure if embedding those images has worked, can someone confirm and I'll have another stab at the photobucket links... Cheers

-

• #14

Not working for me :)

-

• #15

Thanks, can't seem to get the embedding feature to work so I've posted photobucket links until I can figure it out

-

• #16

You've just got to link to the direct image

Try right clicking on the picture, and copying the address that way

-

• #17

Nice one, I've planned this out myself in the past, just never got around to doing it. Are you getting the wheel built for you or just the rim?

Using a wire threaded through a rubber tube, tension it, then weld together is apparently the best way of doing the tyre.

-

• #18

I'm always confused about spokes too. I mean, wtf?!

-

• #19

@MCamb cheers for that, edited the post to suit

@Dogtemple rim will be an aluminium box section from here:

http://www.unicycle.uk.com/penny-farthing/penny-kits/54-udc-penny-farthing-rim-64-hole.html

I could buy the hub from there, but I managed to code the dimensions for square tapers into a CNC program at work, so could potentially be fancy and have a custom hub produced if I can track down a decent sized billet.

@Skülly I reckon being especially nice to someone like Sapim could get me some overly long blanks, although may need to get something tougher than standard (14?) gauge spokes and roll a thread into them

-

• #20

This looks amazing. Subbed.

-

• #21

Madness! Will follow closely😉

-

• #22

Cool, often wondered how you held the two ends of the rubber together.

To get around the comically expensive huge billet of ally, can you make a 3 piece hub and press or bolt the 3 pieces together? Could probably then do the flanges on a rotary table on a mill.

-

• #23

Bit of an update, turned two steerers today, one to suit external headsets and one with a small dimension change to better suit the integrated headset I'm going to try as I'd prefer to use a bmx style headset. No real reason for this other than aesthetics, and because I feel like overcomplicating everything.

Integrated version on the left, external on the right

Top edge camfer:

Looking to gather materials for the rest of the build, few ideas below:

Fork - probably going with four fork legs as ovalised tubing is a pain to get hold of at a decent price in this size. Crown will be twin plate milled from 6mm steel, this should keep the fork nice and rigid and provide enough support for the steerer.

Spine - Ideally tapered tubing from 40mm to 30mm ish, probably just going to be straight tubing though

Rear fork - going to find a straight blade road fork and cut the legs off at the length I need and try to braze to original crown

More to come as and when I make something or it crosses my mind

-

• #24

Printing as a possible alternative to machining a billet?

https://www.lfgss.com/conversations/287457/

... but I've no idea how much it would cost to contract out... -

• #25

Still not certain on the tyre situation, going to have a look at my options.

It's something I thought about, I'd have to generate everything using CNC as all the manual machines I have access to only have Y axis automatic feed, so the flanges would be difficult to turn to a decent finish, this means it would take a lot of time and I don't have much access to these machines for non work related stuff.

Having said that, thanks for putting me back on that track, definitely going to look into it tomorrow to see if it's possible

MrE

MrE drøn

drøn hp93

hp93 Jonny69

Jonny69 jdp

jdp kjlem

kjlem SideshowBob

SideshowBob MCamb

MCamb Dogtemple

Dogtemple Skülly

Skülly Aroogah

Aroogah russmeyer

russmeyer

Being a long time browser of the forum and never really contributing anything, I thought this may be of some interest to some of you...

The plan is to build one (or two) penny farthings, my dad has been racing one a friend built a few years ago, having ridden it aswell I decided out of a combination of boredom and interest to start building one for each of us.

Most of this will be guess work aswell as a lot of asking people in the know of what an ideal design is...

Plan for my own:

54-56" wheel - not sure if my legs are long enough for the bigger wheel as I'm 5'11 so will have to try one out

Custom build all framework - as it's not really an OTP market and I'm an engineering apprentice I want to produce as many of the parts myself as possible

That's it for right now as I'm posting from my phone, will be starting to turn a custom headtube and steerer later today at work to deal with the extra stress around that area on a penny that standard tubing won't cope with very well, so hopefully some pictures to follow soon.

Disclaimer: I am no professional machinist, I'm an apprentice with a couple of weeks experience on a Bridgeport mill and Colchester lathe so nothing will be perfect and I'm sure I'll have no idea what I'm doing most of the time.

Any input or suggestions would be greatly appreciated!