-

• #177

Is it possible that having three spokes crossing at the same point, all laced heads-in, has caused this?

The tensioning/detensioning cycle the wheel goes through while turning under load, could act to stress the hub flange lateraly. I imagine the hub shell is'nt designed to undergo this sort of stress cycle. Radial heads-in causes the same stress, but not with three spokes focusing the stress to the same point on the flange. Pure speculation though, as I really dont know much about the crows-foot pattern. For patterns with no crossing or crossings away from the flange. I would have also gone with heads-in for the improved bracing angle.

Just some thoughts. Still most likely a defect. Good to hear your being sorted with a replacement.

(ED: If the spokes are 'unhappily' crossed. Should'nt a spoke elbow fail before the hub flange?)

-

• #178

(ED: If the spokes are 'unhappily' crossed. Should'nt a spoke elbow fail before the hub flange?)

That's what I was thinking.

It is possible that it was my fault but I asked (^) the guy who wrote the tutorial I used and he said that it was no problem to do it like that. Well, it has led to problems but I dunno what was the cause.

Johnny and broken777 have had their flanges cracked with 3cross.

-

• #179

With a bit of imagination you can picture the two crossing spokes pushing on the radial spoke of the triplet, which transmitts this to the edge of the flange. In reality the forces should be too small, and the the bracing angle far too small, for this to cause the failiure (IMHO). I've heard loads of postive reports regarding the quality of Goldtec hubs, maybe they are having problems controling this quality?

I'd be interested in seeing some stress images of some hubs with different lacing patterns. Surely there are some out there on the interwebs.

-

• #180

With a bit of imagination you can picture the two crossing spokes pushing on the radial spoke of the triplet, which transmitts this to the edge of the flange. In reality the forces should be too small, and the the bracing angle far too small, for this to cause the failiure (IMHO). I've heard loads of postive reports regarding the quality of Goldtec hubs, maybe they are having problems controling this quality?

I'd be interested in seeing some stress images of some hubs with different lacing patterns. Surely there are some out there on the interwebs.

You do mean in bending, right? I think that spokes are so flexible that you can assume they only transmit tensile forces. At least, that's what I would do if I were building an FE model of a wheel. (Sorry if I missed something).

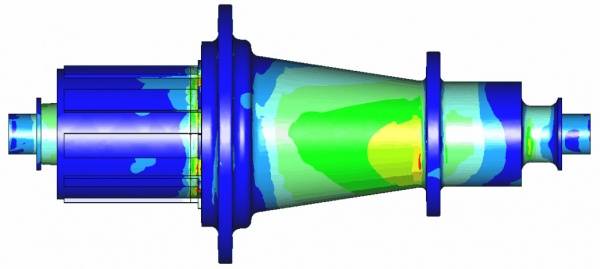

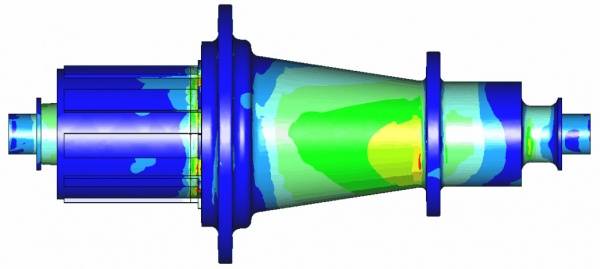

Where is that contour plot from? Looks very interesting.

-

• #181

You do mean in bending, right? I think that spokes are so flexible that you can assume they only transmit tensile forces. At least, that's what I would do if I were building an FE model of a wheel. (Sorry if I missed something).

Where is that contour plot from? Looks very interesting.

Yeah, badly worded. I meant the inside of the elbow of the spoke is pushed against the flange, due to the bracing angle.

The pic is from here:

http://www.m5-ligfietsen.nl/site/EN/_m5__Lightweight_bike_parts/Front_and_rear_hubs/sAction:addtoshoppingcart/jump:1432/art_id:1432.2/quantity:1/custom:Was tempted to use these in my road wheel build. Very light, and well priced, but I cant seem to find a source of straight pull bladed spokes.

)

)

)

)

I'll probably go with a Tune MAG 180/ MIG 70 combo instead. -

• #182

Does the stress patteren really matter that much... Why not just get hubs that don't suck and use any patteren you like? ;)

After several threads about goldtec's breaking I for one will never get one... I'd rather run on-one's - actually I do atm on my winter-wheels, and the cheap hubs never failed me.

Why get expensive shit-hubs when you can get cheap and nice Miche?

-

• #183

Does the stress patteren really matter that much... Why not just get hubs that don't suck and use any patteren you like? ;)

Its mostly bike nerdism.

But the fact is most hub manufactures dislike radial spokes. Whereas most OTP road wheelsets these days have loads of them. This doesnt quite add up to me.After several threads about goldtec's breaking I for one will never get one...

I've read far more positive reports regarding Goldtec hubs, and weighing up the weight/cost/durability(OK mute point on this thread). They're pretty impressive.

http://weightweenies.starbike.com/forum/viewtopic.php?t=50133I'd rather run on-one's - actually I do atm on my winter-wheels, and the cheap hubs never failed me.

Why get expensive shit-hubs when you can get cheap and nice Miche?I've a set of Shimano Deore's which I no idea have many miles I've put on them. I've moved them from beater to commuter to winter bike etc. and lost track over the years. I almost didnt want to open them up to service them before winter, in case I broke the spell.

-

• #184

Its mostly bike nerdism.

Yeah, with some engineering nerdism thrown in too :-) I have been idly considering doing some FE modelling of bike components. I'm sure it has either already been done, or isn't financially a viable idea. Which is a shame, although I haven't actually researched it much yet.

I've a set of Shimano Deore's which I no idea have many miles I've put on them. I've moved them from beater to commuter to winter bike etc. and lost track over the years. I almost didnt want to open them up to service them before winter, in case I broke the spell.

Oh good. I just got some Deores for my MTB and I can't be bothered to buy more hubs anytime soon...

-

• #185

-

• #186

Good on 'em. You gonna build it up silly again? :)

-

• #187

I'm not sure that I deserved it though, but as a sacrifice to the Wheel Gods, I will re-lace my wheels into ordinary 3-cross, if I really get this hub shell.

. -

• #188

hehe

-

• #190

you need to pop off that cover with something, then just tap the end of the axle, one side of bearings should come out, then put axle back in and tap out other side.

-

• #191

That cover ain't shifting. I have already bent it. Keep going?

-

• #192

er i don't know then. pliers wrapped in electric tape to not scratch it?

-

• #193

-

• #194

That cover ain't shifting. I have already bent it. Keep going?

Could just be seized with crap. Have you tried spraying some WD40, or similar, in the gaps and leaving it for a while*.(*I realise this is the bike equivalent to an IT help desk's 'have you turned it off and on again')

-

• #195

The caps are just held on by an o-ring so they slide off, but they're quite a tight fit. I usually use pliers or mole grips with something to protect the aluminium like a bit of inner tube or a rag. It looks like you've made quite a mess of yours TBH, but you might be able to straighten it out when you get it off.

-

• #196

-

• #197

you've laced it wrong.

-

• #198

The other side is laced right

-

• #199

^ i am unsure of the seriousness of this, and so feel quite silly explaining that my post was a joke at the whole incorrect-yet-correct crows feet lacing debacle espoused in this thread.

-

• #200

It doesn't matter on a fixed wheel, but on a wheel for a derailleur bike the drive side pulling spokes should be laced inbound because they get tighter under power and pull the third (outermost) crossing towards the centreline of the wheel. If you lace them as EFC has on the side facing us in the pic, the pulling spokes when using that side as the drive side will pull the crossing away from the centreline - this can potentially cause interference with the derailleur cage when applying high torque in bottom gear.

In short, I was joining in with your joke, because it really doesn't matter on a fixed wheel.

Smallfurry

Smallfurry ehren_fried_chicken

ehren_fried_chicken Cupcakes

Cupcakes

hippy

hippy

Mrlemon

Mrlemon

gbj_tester

gbj_tester

For people, who are interested, I emailed Rob Torres about the lacing and he sent me this back: