-

• #127

Thanks for the compliments people and for the info RPM. I didn't notice any asymmetry. I'll have to look again.

-

• #128

I love your old school vernier and your scales. Thank you.

-

• #129

Thanks for the compliments people and for the info RPM. I didn't notice any asymmetry. I'll have to look again.

It's almost imperceptible, but you'll find it when you dish your hub in the centre. You may need slightly more tension in one side.

Mine seem fine after riding today -

• #130

Subbed. That is such a nice looking frame, can't wait to see the thing complete.

-

• #131

My 88mm rear was marked drive and non-drive, it's done ~2,000 London miles laced to a track hub now.

You'd have to ask Jim which way round he did it.

-

• #132

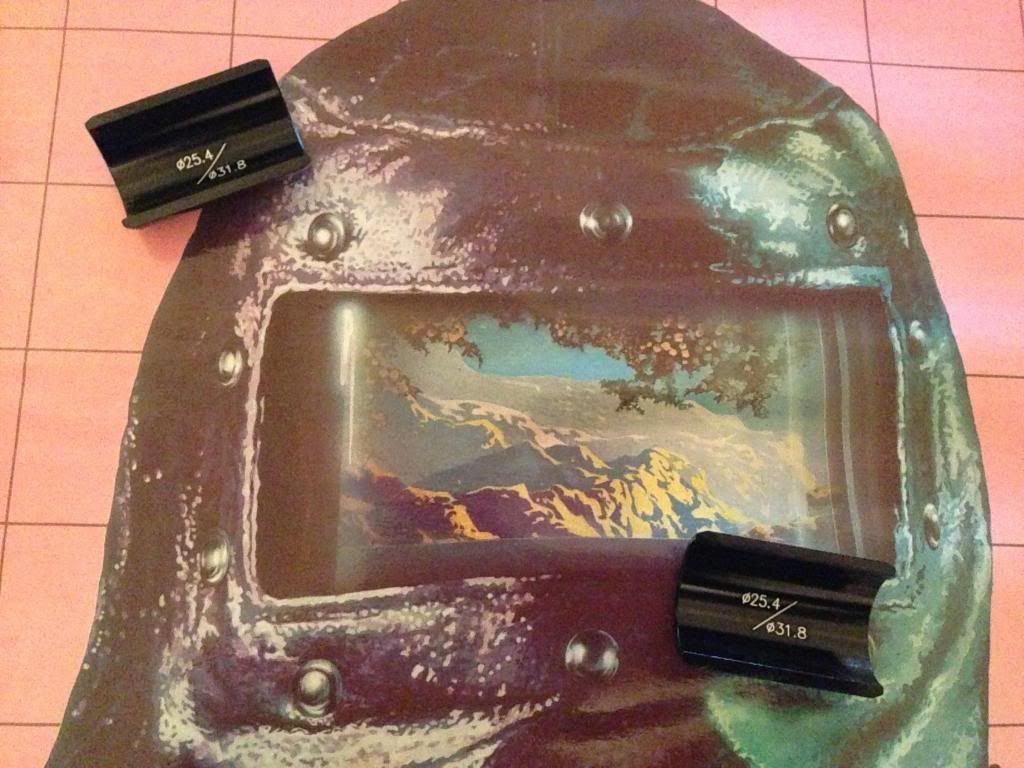

alpina sprint bars? OS clamp and 33cm

-

• #133

That's a pretty good idea, they do come in 38cm too, but I have bars already.

Actually, I've decided on and ordered everything now. The only things I haven't ordered are the spokes because I don't know what length I need yet. -

• #134

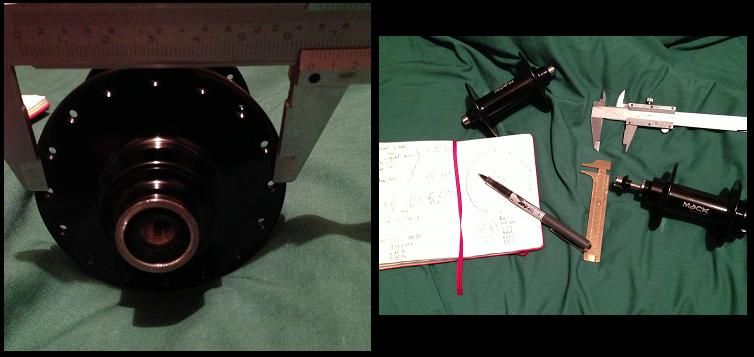

The hubs have arrived!

Now that I have the hubs in my hands I can take all the necessary measurements to determine the spoke lengths. But to take the most accurate ERD measurement I want to use exactly the nipples I will use in the finished wheels. Anything else could sit differently in the rim and produce an error. The error would be slight, but why not take as accurate measurements as I can. Also, I am not fully sure of the exact dimensions of the nipples and these are also critical to spoke length.

Lovely lovely hubs. So smooth.

-

• #135

Actually I've had the hubs for about a week now. In the mean time I've been trying to get my hands on some nipples.

I mentioned the measurment issue to DCR wheels (David Hunt) and he helpfully sent me two nipples in advance of my spoke and nipple order.

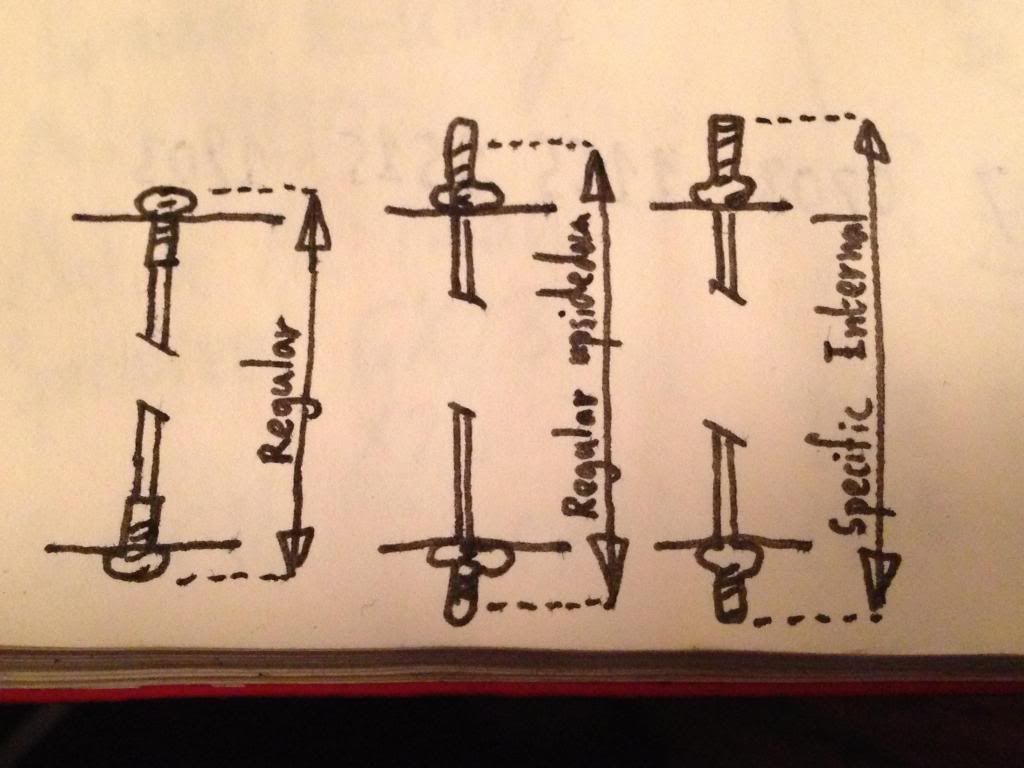

They look like this (next to regular nipples for comparison):

Note that they are not just regular nipples without a slot. The hub end is bevelled in a way that will account for spoke tangents. The thread is not where it would be with an upside-down nipple. It does not start right at the hub end and and does run right to the rim end.

These things plus the location of the nipples mean that ERD and ERD measurement is bit different to normal.I have measured the ERD like this:

I put two spokes through two opposite holes and put the nipples on the ends. I marked on the spokes how far on I put the nipples. I pulled the two spokes together and made marks on them to show where they met.

I took the nipples off, took the spokes out, put the nipples back on to the same point and then held the spokes to a tape measure with the marks lined up. I checked all the way around each rim.

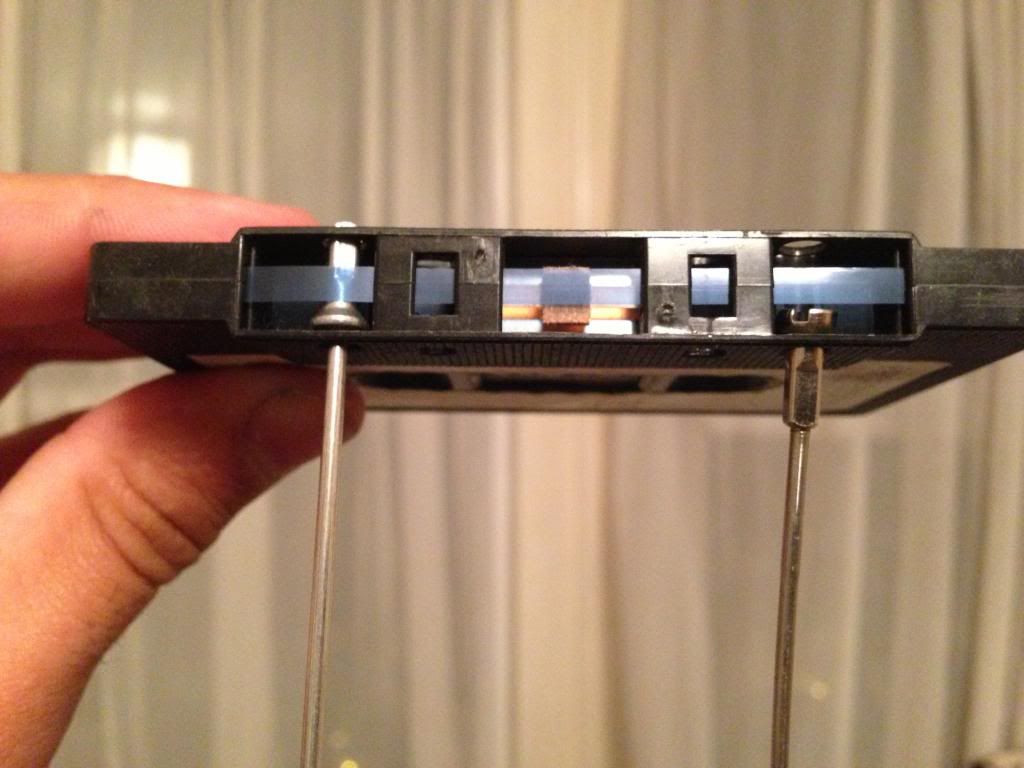

Some must be added to this length though; because of the nipples being inside the rim the spokes need to reach that bit further. As you see:

-

• #136

Placing spoke order now.

So close!

-

• #138

can't wait to see this

-

• #139

Any developments ?

-

• #140

I'm just waiting for the spokes to arrive.

In the meantime I'm thinking about how much of the bars I will wrap.

And maybe today I will make a spoke holder to stop the spokes from twisting during the build. The spokes have a stated width of 0.9mm and the blade of my wood saw is 0.7-0.8 mm thick, so I should be able to come up with something. -

• #141

Today somebody asked me about the nipples in relation to truing wheels built with these rims.

So, just to be clear, if anybody else was wondering, yes, to true a wheel built with these rims or any other rims that require internal nipples you need to remove the tyre.

The rims require internal nipples because the holes are only big enough for spokes to fit through.

There are two reasons for this design: One, having the nipples inside gives a slight aero advantage and two, the smaller holes mean the rim is stronger at this point so higher spoke tensions can be used and/or the rim can be made more narrow here and/or the material can be made thinner and thus lighter.

Or put another way, rims of this shape and material would be too weak if regular size holes were drilled in them, smaller holes are drilled and the rim remains strong. It just means having to do things a little differently.

Yes, it is a major hassle to true a wheel that requires a glued on tubular to be removed to do so, but this is the price of the above mentioned advantages.

-

• #142

Where exactly are these spokes being dispatched from?

3+ weeks delivery time?!

-

• #143

If the nipple threads are tapped with unicorn horns then the spoke threads must be rolled on with the opposite end of the unicorn. Sapim has to specially prep. the right beast from it's blessing deep in the Antwerp woods. I suppose this takes some time.

Only explanation I can think of.

-

• #144

The spokes have arrived!

However, I've let the 'workshop' get into a bit of a state, so before assembly can commence, some tidying up is in order. I've started that and almost finished, but I got distracted and decided to make a spoke holder.

Sub-Project (spoke holder)

I haven't built with bladed spokes before, but I've read that having some way of holding them during tensioning to stop wind-up is helpful. Some people use pliers possibly with a layer or two of tape over the grips so as not to scratch the spokes and some people use a specific tool sold by the spoke manufacturers. I think paying £5~15 for a bit of plastic with a slit in it is a bit silly. So I decided to make my own.

I wasn't sure what shape to make it at first, so I bought some plasticine to play with and consider different comfortable shapes. After this I quickly decided that actually some of the nicest tools to use are the ones that aren't particularly shaped to accommodate the human hand but have that straight lines, angles and fewer curves, for example a screwdriver with a hexagonal handle versus one with a circular handle.

Anyway, I decided to amputate one of the legs from a chair falling apart where I live and use that for raw material. Here is the thing, in the rough:

-

• #145

I've done some sanding over a couple of lunch breaks and now it looks like this:

I want to apply something to protect it. I had a little look around for some varnish; I decided to get a bottle of raw linseed oil. I've put some on a test piece to see how it works and if I like the result I'll cut the slit in the spoke holder and then apply the oil all over. I thought I would cut the slit(s) after varnishing if I used anything heavier, so as not to clog up the critical space.

I have very little free time right now, so bike assembly and wheel building is being delayed.

My final component considerations are about bar tape. I like old fashioned cloth tape, but black cloth tape fades so quickly. I like cork too. I might use that.

-

• #146

FLRN HSSL is doing a yellow electrical tape/perforated bar tape combo that will look amazing imo - you could do the same with a red base layer

-

• #147

how long can it take to build up a wheel/bike??????

-

• #148

Excellent documentation Polka dot! Makes for great reading.

-

• #149

Right, I have an update, including several detail pictures, but this page is already way too picture heavy, so an interlude:

Polka_Dot

Polka_Dot Itisaboutthebike

Itisaboutthebike rpm

rpm Dammit

Dammit Panda

Panda

hma

hma ZenithE

ZenithE Crop

Crop Eingang

Eingang detsamma

detsamma

Ha, I only know as I was going to ask the same earlier but thought I better check back.

I can't help but think a perverse setup like DA7900 with Goldtec ring would be boss....