-

• #2

the way i did was to have the spokes tensioned to about 80% (lose ish) then go for a gentle ride to get everything seated properly (this may not be advised, but it makes sense to me).

then i tension the wheel to what i reckon feels 'tight'.

N.B.

check the vertical trueness. It's really impoortant.Most factory wheels and such are always too lose anyway, so ignore them if you can.

-

• #3

i haven't got a tensiometer so checking the tension with my hands. i guess trying to determine what is 'tight' comes with experience.

as in vertical trueness do you mean radial trueness? i'm using a stand so have been able to check that as part of the process.

-

• #4

just screw each nipple the same amount. a good idea is to tag on spoke tape so you know where to begin and end.

Adjust trueness as necessary as you go along. little by little.Like i said, vertical trueness is really important since it's much harder to adjust than lateral trueness when the wheel is at full tension. so keep a close eye on that.

P.S.

Sheldon Brown has a really thorough article on all this. I suggest giving it a read.

-

• #5

If its a fixed wheel it needs to be relatively tight. I would say generally 6/7 full turns from the end of the htreads (if the spokes are correct size!) Dont compare it to a geared bike wheel.

-

• #6

Do it up fairly tight (enough for them to 'ping'), but dont worry too much as youll have to do it again soon after the spokes have bedded in

-

• #7

Do it up fairly tight (enough for them to 'ping'), but dont worry too much as youll have to do it again soon after the spokes have bedded in

if you build your wheel properly you should not have to do this.

true - stress - true - stress - final true - ride - be happy.

-

• #8

for the stressing bit you don't need to ride it

just put it on the floor axle down and hold the wheel at 9am and 3pm ( clock face ) and push down

spin through 10 degrees and repeat until you have been all the way around the wheel

you'll hear pings and twangs as the spokes re seat themselves

feel a wheel that is already built and match the tension on that one i guess

couple of mm's play on each spoke ? -

• #9

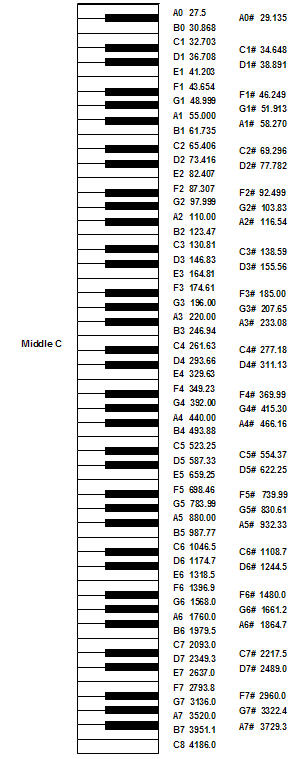

one octave above middle c

-

• #10

for the stressing bit you don't need to ride it

just put it on the floor axle down and hold the wheel at 9am and 3pm ( clock face ) and push down

spin through 10 degrees and repeat until you have been all the way around the wheel

you'll hear pings and twangs as the spokes re seat themselves

feel a wheel that is already built and match the tension on that one i guess

couple of mm's play on each spoke ?i've been stressing by squeezing pairs of parallel spokes with my hands. haven't been hearing any twangs though. should i be?

will try the tone thing, trying not too overtighten the spokes but overtight is better than loose i spose. -

• #11

for the stressing bit you don't need to ride it

just put it on the floor axle down and hold the wheel at 9am and 3pm ( clock face ) and push down

spin through 10 degrees and repeat until you have been all the way around the wheel

you'll hear pings and twangs as the spokes re seat themselves

feel a wheel that is already built and match the tension on that one i guess

couple of mm's play on each spoke ?dicki clearly explained this better than me.

-

• #12

i have just built up my first rear wheel, is going well, almost too well. open sport to zenith

i have it trued to within a couple of mm laterally, and vertically i have had no need to do any.

my questions are, is it unusual to have to do no vertical truing?

also, when i have it perfectly true, to tension it more should i just go round the whole thing doing 1/4 or 1/2 turns?

is it necessary to get its dish checked (0)? i have been using my frame with zipties for a truing stand, and it is in the middle of these.

thanks

-

• #13

the vertical truing shouldn't be an issue with new stuff and unless the rim is truly buggered it shouldn't be neccessary with an old rim as long as you have done everything carefully and methodically and you have 24 / 28 / 32 / 36 spokes all of equal length then there should be no need to true the up and down just the side to side

as for dishing that's really only neccessary with road wheels as they aren't symetrical track hub are symetric (SP?)

-

• #14

thanks,

"also, when i have it perfectly true, to tension it more should i just go round the whole thing doing 1/4 or 1/2 turns?"

i plan on using a tuner to get he correct tension which is apparently 440Hz (294mm DB spokes) http://www.bikexprt.com/bicycle/tension.htm#pitchtable

also, bmx wheels are higher tension yes?

-

• #15

i had to take my newly built wheel to jimbilly - though it felt sound i thought it best to get an experience eye cast over it

The first time i took it to him i had laced the spokes to the wrong side of the rim but got it true to less than .5mm - i had used an old wheel as the guide for tension but Jim explained that as spokes tend to loosen up in use that a used wheel is possibly a little slacker than you would wish to build a new one.

used one of those spoke tension measuring devices inthe workshop, the first time i had built it up and it was measuring around 20 (and now i cannot remember the units). Hillbilly suggests around 25 is an appropriate tension - so when i rebuilt it with the spokes to the correct side of the rim I made it tighter and the spokes came in around 23 or 24 (aargh it fucks me off to forget the units).

-

• #16

hertz ( hz )

-

• #17

nah jimbilly uses

ciderz ( cz )

-

• #18

There are no units on the spoke tension meters I’ve seen, u have to convert the reading on the meter using a table (based on which spokes u r using).

-

• #19

I thought spoke tension was usually measured in 'Newtons', and the spokes of a track wheel should be about 1000 newtons?

-

• #20

this is the meter reading to spoke tension conversion table for the park tools meter:

http://www.parktool.com/products/documents/TM-1_Table_WEB_4-7-09_200947_72578.pdf

-

• #21

absolutely no idea on wheel building (hopefully will one day), but casting my mind back to school days tensile strength is measured in Pascals [Pa] - same as pressure (e.g. for pumping up tyres)

note - could be, and probably am, completely wrong

Hz - is a frequency measurement

-

• #22

i just built my first wheels up too.

to get the tension i just plucked a spoke and checked the 'ping' against my housemates wheelset.

2 months later they're still fine... -

• #23

i was thinking of the ping the spokes gave off when you ting them

i guess you could tune spokes using a tuning fork, get them all ringing at middle C or e-flat that would be a way to get them all tensioned the same

just need to choose the right tuning fork -

• #24

is there a question of different spoke lengths giving off a different pitch? like a guitar?

-

• #25

obviously not to the extent of being musical ;)

Dylan

Dylan PatChurch

PatChurch DFP

DFP _Zed_

_Zed_ dicki

dicki freddo

freddo dancing james

dancing james hael

hael forms

forms DirtyD

DirtyD Tobyanstis

Tobyanstis

Just nearing completion of my first wheel build, an open pro laced to a rear double fixed phil.

Everything has gone smoothly so far, and currently at the final tensioning stage.

Looking for some advice on how tight i should have the spokes, have read various builders talking about comparing the flex in middle of a pair of spokes on a wheel you trust and tensioning to that, however finding this quite tricky. Has anyone got any tips?

Also as the hub is double fixed, should i be thinking about having a stronger drive side and any dish?