-

• #202

Already on "ignore".

-

• #203

Thanks.

My guess is that 57mm is standard, as they refer to 57mm on their site and it's the slim version that is differentiated.

There seem to be a few 54mm specific things (eg Middleburn spiders), so you're likely right about there being a demand for a 54mm carrier.

-

• #204

The slim option appeared about mid last year from memory. I had only a few weeks earlier paid thorn to install the regular splined carrier and was preparing to start dicking around with my chainline when the S version arrived on the shelves so I ordered one and swapped it over.

Here's the S

https://www.sjscycles.co.uk/sprockets/rohloff-splined-sprocket-carrier-slim-8540s/

Here's the Non S

https://www.sjscycles.co.uk/sprockets/rohloff-splined-sprocket-carrier-8540/Anybody want a barely used 57mm splined carrier for Rohloff?

I'd also read on the Thorn forum that the S version "might" have been developed for the Hebe chaincase lot as the 57mm chainline would stop the chaincase working as it couldn't be mounted.

-

• #205

Sorry, not to doubt you or Mr Whittle but are you sure he can rebuild/repair the internal lump?

From what I read they (Rohloff) just point blank do not do, sell, list, fit or supply any of the composite parts of the internal lump to anyone nor will they undertake that work themselves, they just diagnose either internal lump ok, leave it in or internal lump malfunctioning, take it out and put new one in.

I can perhaps understand (see below) why they work this way I just don't like it.

I imagine the reasoning is something along the lines that Rohloff has a reputation for being a very reliable hub and they want to safeguard that, even when the hubs do go wrong. Rather than sell spare parts, the fitting of which would be a skilled, time consuming job which may only partially fix a problem, they choose to have one solution which is not a difficult job at all, can be done very quickly and which will return the hub to working like new. In warranty cases it removes the risk of missing a minute detail that causes further breakdown and the costs involved in fixing that problem plus it keeps the customer satisfied and confident in the hub and singing its praises.

Removing the possibility of buying spares for customers means that if their hub goes wrong out of warranty, they have to pay through the nose for the same fix which they might moan about for a bit but then they also end up with a hub which works like new, which they have confidence in and of which they will speak highly.

-

• #206

Any of you nerds need a battered 8 speed alfine hub? I have two that'll be going in the bin. Cannot vouch for either but they're free and potentially serviceable. Collection from N1 / E5 etc.

PM if interested pls

-

• #207

@M_V I'm reasonably sure he can service the lump. I had quite a few conversations with him when he was working on my hub and we discussed him going to their factory for training etc. He also told me a story about resucitating a hub that had been really badly abused was effectively dead.

However all that said if the hub is still an issue then I'd still say Dave's the best person to talk to and ignore me.Is the hub an issue still?

Incidentally have you seen these?

http://forums.mtbr.com/internal-gear-hubs/rohloff-strip-axle-rebuild-videos-english-659526.html -

• #208

Yeah I think the hub is still an issue.

It's my colleagues rather than mine and I think the potential £700 bill has put him off of working on or thinking about it just now.

Is the email address you have for Dave just Dave@sjscycles.com?

I reckon a thorough degrease and relube might bring it back to life but he's not too sure about putting anything not strictly branded Rohloff near the hub as the manual says not to :S

Yeah I'd seen the videos, found them via another route, just without a source for the bits, there's little to be gained by stripping it down any further right now.

-

• #209

@m_v yep that's the email I have for him. Did you and your mate follow the regular "service" procedure, i.e. flush oil (50ml I think) and run it thru all the gears and then drain the flush oil and replace with the proper oil?

If it's an external gearbox it might be worth remoing the gearbox and changing gears using a box spanner and that way you can rule out cable/shifter issues.

I'd avoid a de-grease the flush oil is much safer and provided its run through all the gears should reach everywhere inside the hub.Isn't the guy at Kinetics a Rohloff fan, he might be an option for advice?

let us know how you get on.

-

• #210

Yeah we've had the gearbox off and shifted it with spanners.

I'll suggest the oil flush to him then, he should be a bit happier doing that I imagine. I just thought degreaser as the remaining oil is quite grubby (though not with metal particulate).

I dunno how much of a rohloff fan Ben is, worth taking to him at least though. Not sure when I'm next working with the hubs owner but will bring all this up.

Cheers.

-

• #211

Will a rohloff/alfine work in a 135mm track/sliding dropout all city nature boy disc?

-

• #212

Alfine, definitely.

Rohloff, probably, with the right bits.

-

• #213

Alfine, definitely.

how would I run the gear cable without modifying the frame?

-

• #214

It's a solid outer from shifter to cassette joint (hub) so just zip tie it along the chsibstay and up the down tube.

-

• #215

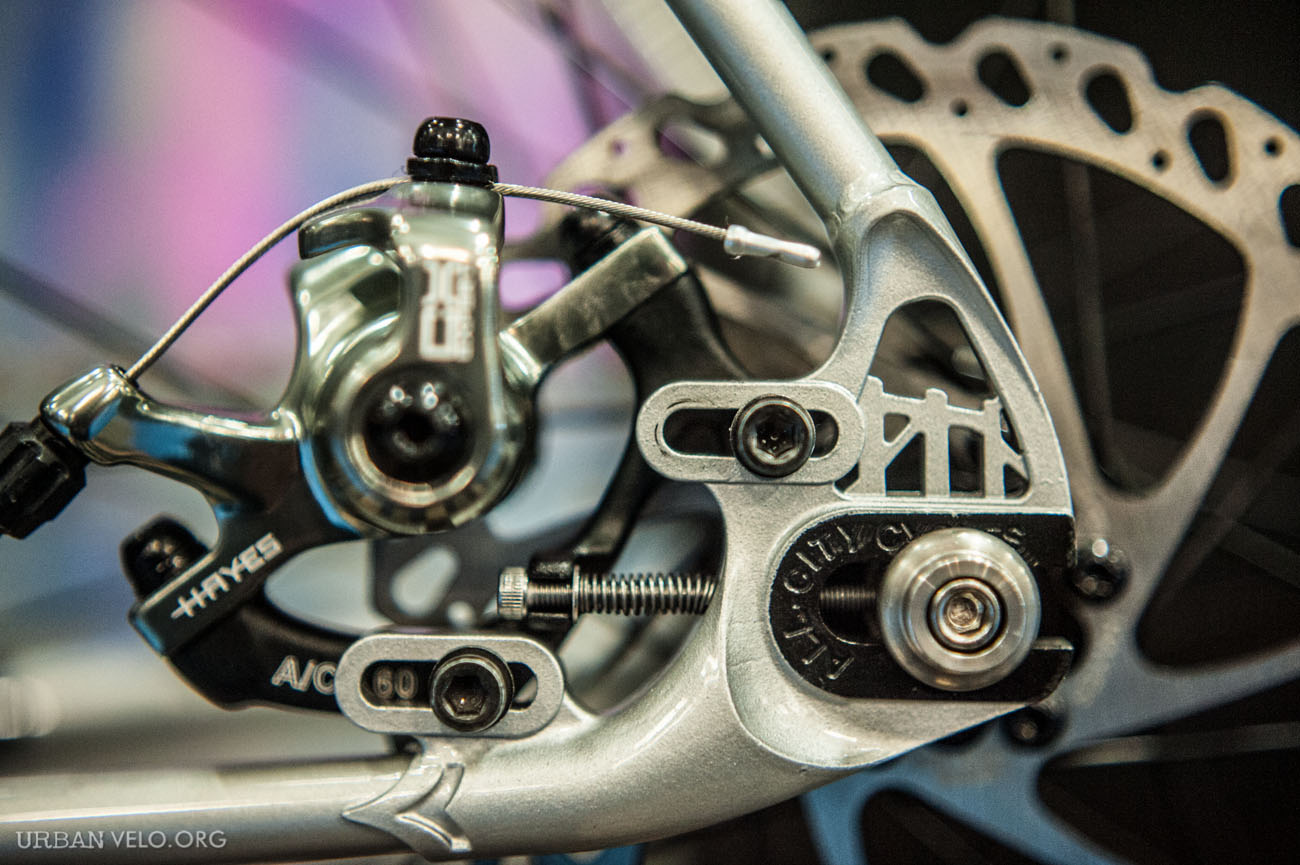

You'll also need the right combo of disc brake adaptor and rohloff torque plate.

Theres the monkeybone which is easy but you need iso brakes. -

• #216

do tell more ..

-

• #218

ah I think I know about monkeybone .. i.e. their PM to IS adapter right? What about the torque plate? And is axle plate = torque plate?

-

• #219

Not sure the monkeybone is a pm to is adaptor it simply allows you to hook the axle plate into the monkeybone to stop torque as it has a cutout. Ive got a rohloff on a singular gryphon which has standard dropouts and a monkeybone and longer axle plate. The standard axle plate isnt long enough to reach the monkeybone cutout. Rohliff have just brought out a new brake adaptor and it might be for PM brakes but ive not looked into yet.

-

• #220

The Monkeybone a combined torque arm and brake adaptor: IS frame to PM brake.

It's only compatible with a Speedhub with the OEM2 axleplate.

At least I hope that's right, because that's what I've ordered: The Shipwright's got me worried now...

-

• #221

@scilly.suffolk aint silly.suffolk, u r spot on. Sorry was trying to do this from memory and getting my lingo mixed up and the few beers i had didnt help.

@amey not sure how easy it would be but if you want you can try my monkeybone /oem2 axle/hub etc into the frame. -

• #222

Phew!

Sorry was trying to do this from memory and getting my lingo mixed up and the few beers i had didnt help.

Never apologise; never explain.

-

• #223

Readers. Happy with the Sram hydro/Gebla combo so far but will probably go flat mount when they're available.

Spirit tubing and lightish wheels so coming in around 10 kg. Have all the bits to try out carbon drive in the future and likely to change to tubeless at the same time.

-

• #224

What sprocket would I need with 11sp Alfine used with a 32t Chainring to replicate 40t 1x 11-36 set up? Gear calculators are so confusing ..

-

• #225

With a 32mm tyre, 40 x 11-36 gives you a range of 29.98-98.31 gi

Alfine 11sp with 32 chainring and a 17t sprocket would give you 26.3-107.4 gi

Scilly.Suffolk

Scilly.Suffolk TheShipwright

TheShipwright M_V

M_V picco

picco amey

amey BareNecessities

BareNecessities @cornelius_blackfoot

@cornelius_blackfoot

My hub has the splined carrier and has a chainline of 57mm. Can have a look on the box, to see if there's any mention of what model of carrier it has.

I don't remember there being a 'slim' option at the time. Might have come about later, due to demand.