-

-

Ok. let's hypothesise that I've been an idiot and bought a band-on front mech without checking the diameter of my seat-tube and found it is too big. Hypothetically.

If this were to have happened, is it possible to shim it out? It's a 2007 Chorus on an old steel frame (whatever the standard size is, I've checked a few steel frames of the same vintage and it is too big for any of them). Or is this likely to have been designed for a newer standard tube size (oversize alu or something). As far as I know it's just the standard chorus band-on. Or are they all designed to need shims. I've never bought a front mech 'seperate' so never had these issues.

Hope someone can be bothered with this frankly pretty dull problem.

Cheers

-

I've got a Miche on order now. Fingers crossed. I have had a run round the BB shell with some verniers, and it seems that on this particular frame it wouldn't be possible to cut more thread without milling out the hole to the start dimension for cutting the thread. The diameter in the midsection is substantially (maybe 2mm) smaller than in the threaded sections, suggesting they didn't mill out the initial bore for the threads all the way through after casting/welding the shell, but only as deep as they wanted the threads. Having had a look at a zeus book, you would need to bore out the bb shell a little, in the process of which you would probably muck up the threads. Even with the luxury of an onsite workshop at work, I can't really be bothered with the hassle of asking the technicians. Just hope the Miche will fit the bill, looks like it should.

Gav86, hope your Peugeot doesn't give you similar problems... I'll let you know how I get on

-

-

OK, hope this sheds some light:

The cartridge is a Token 111mm English thread. The Bike is a 1989 Peugeot road frame with an English thread BB, I have verified this. The problem is twofold. Firstly when you try to insert the cartridge, the following flanges will not pass any further than the threaded section:

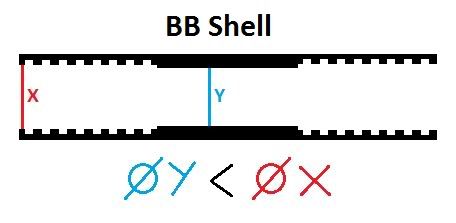

It appears that the diameter of the middle section of the shell is smaller than the threaded section, like this:

And since the flanges are at the same diameter as the threaded section, they will not fit through.

Secondly, when I take off the removable thread and try screwing it into the shell, it goes in almost all the way and then stops about 5mm out. This suggests that the threaded section of the shell is shorter than the threaded sections of the cartridge, so I'd have been 'screwed' even if the thing fitted through. The shell is DEFINITELY english 68mm, and the threads are DEFINITELY sqeaky clean. As I said, the thing screws in beautifully, it just doesn't have enough thread in the shell to take the whole thing.

So basically the token will have to go into something else, that much is sure. But what WILL fit? Any suggestions? Obviosuly an 'old style' bb only requires the axle to pass all the way through, so the clearance inside would not be an issue. And presumably this was the original sort of BB on the original bike.

Sam

-

So I have tried to fit a cartridge-style bottom bracket into my frame, and the long and short of it is that it won't fit, despite the fact it is the right threading. The cartridge won't go all the way through the BB shell. So I am thinking I need an 'old style' BB with races and cups. This is for a campy chorus crank, so needs to be ISO taper 111mm. Does anyone know where I can get a good quality bottom bracket of this sort on eBay or elsewhere, I wouldn't know what to search for (all the results are cartridge type unsusprisingly.)

Cheers

-

-

-

-

I have a set of Chorus cranks identical to those in the following image (right):

http://i141.photobucket.com/albums/r77/hilarystone/Ofmega-CX-Campag-Chorus.jpg

Does anyone know what length of BB spindle these need?

Cheers.

-

-

-

After a set of pedals and straps to go with campy chorus groupset on an 80's steel frame. Doesn't have to be campy, but something along those lines in terms of style. This kind of thing:

Doesn't need to be amazing nick, looking for something fairly nice though with the cage and straps to fit vintage chorus crank. Bike colour scheme is all black and alloy.

Also wondering if anyone has some 1" Olmo forks kicking around in 700C for a 59cm frame. Looking for the chrome ones in decent nick with the Olmo logo embossed and enamelled into the top. Ebay has thrown up nothing.

Would have to be willing to post unless in Southampton area.

Cheers.

-

Hey all

I have some pretty nastily pitted olmo forks from a vintage (probably early 80's), columbus tubing:

1) What am I likely to pay to get them stripped and redone (triple).

2) Where would I get this done (anyone got experience)

2) Will they be safe with the extra metal taken off?

3) Does anyone have any spare olmo forks in decent nick or know where I might find some? (Looking for some nice ones with the logo embossed on the shoulder)

THANKS.

-

Hi all

I am putting together a bike with some campy mech on a nice 80's peugeot frame. I have a 10 speed chorus derailleur and chorus crank that I want to use, question is, would it be ok to use a rear hub with a 5 speed block? I'm using friction shifters, so is it just a case of setting the upper and lower limit screws to account for the narrower block? I've heard that there's some issue with jockey wheels when you try to mismatch. The secondary question is that if the answer is no, and I have some wheels with a 5 speed screw-on block, will I be able to find a 9/10 speed campy block that will still fit between the dropouts (130mm, using old Record hub)?

Cheers

-

-

Haha, I can relate to this business. I am currently trying to find bits to build up a late 80's peugeot frame. Does anyone know what is likely to fit between the rear dropouts in terms of modern wheels/hubs. I'd prefer just to buy a complete set of 700C wheels for some campy cranks and mechs I have already, but worried that the dropout spacing might be a bit narrow to fit a modern freehub/cassette. Anyone know if this is likely to work (I can check for tomorrow the exact spacing.) I'm pretty clueless about what kind of dropout width a modern freehub is likely to need, since I've never used anything except threaded freewheels before.

-

-

I would suggest against using lacquer if you want your job to last more than a few days. Even if you take great care with the prep, I still find the laquer is seriously brittle. I have gone the matte route on the last couple of bikes I have done, used the toughest rattle-can matte I can and given it as many coats as possible. This seems to be a lot more durable. I hate getting a beautiful finish with the auto lacquers and then having it ruined the first few lamp-posts you chain your bike to.

Does anyone know of any really durable clearcoats you can use if you just want a bare metal bike? Lacquer on bare metal is obviously a stupid idea, but it got me to thinking that there must be some more bombproof straight-to-metal varnishes that would do the job, even if they were paint on.

-

-

-

-

LFGSS

London Fixed Gear and Single-Speed is a community of predominantly fixed gear and single-speed cyclists in and around London, UK.

This site is supported almost exclusively by donations. Please consider donating a small amount regularly.

Hi

Got an nice old Olmo frame for very little money, and it is sound apart from the BB, which has quite a bit of rusting and greasy much on the threads (probably from lying around in a damp garage). Tried getting a new BB in and it wasn't at all happy after about 8mm. Does anybody know how much rust is 'too' much to render the bb defunct? Would it be possible to use phosphoric acid gel to de-rust it, and then maybe get a LBS to tap out the threads again, or am I going to have all sorts of nasty loosening issues from the material lost to rusting? (Loctite?) The frame is not worth having a new BB brazed in, but definitely a basis for a pretty nice bike if this can be sorted. If all this fails, has anyone had any success with those 'expanding fit' BB's for knackered BB shells?

Thanks

Sam