-

• #2

Hmm, am I missing something. The spokes in the picture don't look crossed to me; all silvers seem to cross on top of blacks (unless this is a 'before' pic?).

Handy info on the build though, I'm contemplating the same pattern for my next rear, and was wondering about crossings.

-

• #3

Hmm, am I missing something. The spokes in the picture don't look crossed to me; all silvers seem to cross on top of blacks (unless this is a 'before' pic?).

I can see that half the silver spokes are above the black spokes and half below.

You need to take your eyes out and scrub 'em.

-

• #4

I can see that half the silver spokes are above the black spokes and half below.

Well yeah, but I'm only looking at one flange. The other side's above is my below, or vice versa.. or their silver is the new black.. or above the black is below... or maybe my brain needs scrubbing?

-

• #5

+

-

• #6

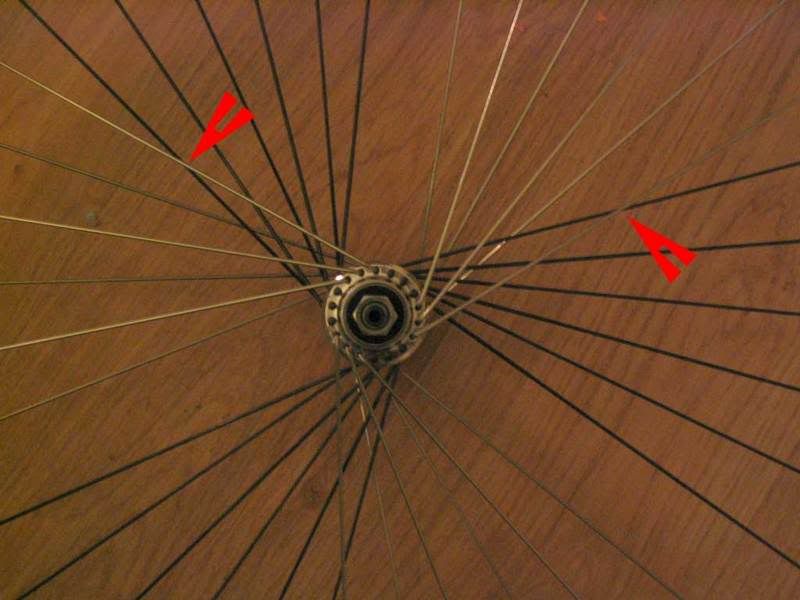

This is actually the before picture, the arrows show where I had to cross the spokes (cross as in twist over and under, as you would a standard crossed spoke, not wrapped around each other like you would for a snowflake). The other spokes "cross", but in reality, they just pass each other, they're not actually twisted around each other.

I tried to take an after picture, but bizarrely it looks exactly the same. Some sort of weird optical effect triggered by the black spokes and the silver stainless spokes.

The spokes are a bit odd since each alternating group of three is a different colour, or rather all the internal (leading spokes) are black and the outer (trailing) spokes are silver. It was a very nice wheel, since in bright sunlight the spokes flashed enough to "strobe" and at certain speeds you got the distinct impression, looking down on it (and from the side) that the wheel was spinning backwards. -

• #7

Nice to know it seemed solid enough, I'm tempted to try a 3-leading 3-trailing pattern on my new build (Rigida SX100 off fleabay and formula type hubs) , but being a fat bastard (and the rims being very low profile) I need something pretty strong.

do you think crossing that last spoke of the second cross may make for a stronger build too, I think crossing all the intersection would be a little harsh on the spokes.

-

• #8

My front wheel = 3l 3t.

I laced all my spokes, and agree it takes a little time to get it true - the effective length of all spokes is different whereas 3cross are all the same. However it has taken everything thrown at it even built up with a cheap rim too - Open sport. I've done about 3000 miles on it so far and it's still true. It's even tougher than the forks it was running on which have broken!

I'd build this pattern again.

As a side note I also run a 3x crows foot in the rear, but sometimes run a standard 3x. The crows foot seems much stiffer.

-

• #9

Nice to know it seemed solid enough, I'm tempted to try a 3-leading 3-trailing pattern on my new build (Rigida SX100 off fleabay and formula type hubs) , but being a fat bastard (and the rims being very low profile) I need something pretty strong.

do you think crossing that last spoke of the second cross may make for a stronger build too, I think crossing all the intersection would be a little harsh on the spokes.

I remember that during the build there were two issues.

If you don't cross at all what you are effectively building is a radial wheel with slack spokes and a twist applied and then another set of "radial" spokes with a twist applied in the opposite direction.

I was able to get the wheel true with no problem, but de-stressing the wheel, by laying it on the floor, pressing down on the rim, spinninging it around and repeating at 4 or 5 spots around the rim, just pressed the rim into a pringle.

This had never happened to me with a 3x build. The spokes are just too long to support the rim without crossing.I stripped back the wheel and tried to rebuild with the spokes crossing at every intersection. Since I used a small flange hub, this proved impossible since the crossings were just too tight. The first crossing would be right on the flange.

The 1 cross per group of 6 spokes was an easy compromise and held up with no problems. If you moved to two crossings, as you suggest, it would all take place on one spoke (the one arrowed), which would shorten it quite a bit (you'd need to use one longer spoke to take this into account).

My gut feeling is that if you are heavy or hard on gear, then go 3x and then you just don't have to worry about the wheels. If you want to try it, the rim depth is not an issue and a lrge flange hub, like the Formula will give you a stronger build because you'll have shorter spokes and effectively more triangulation, both across the hub from left to right and from spoke group to spoke group (bigger gaps between spoke holes).

If it all goes wrong, tear it down and rebuild 3x, you've nothing to lose and a back wheel is not going to "fail" by folding up or anything scary. You just might snap a spoke head off and have the rebuild. I'd much rather have a rear wheel fail than a front wheel fail.

-

• #10

I never really worried too much about it, but I did notice that the bike handled very differently when the tyre pressure was a bit soft compared to pumped up hard.

This is not a good sign IMHO. Surely it indicates that a lot of the strength came from the highly pressurised tyre and not the rim and spokes?

-

• #11

This is not a good sign IMHO. Surely it indicates that a lot of the strength came from the highly pressurised tyre and not the rim and spokes?

That's common on tubs as the tyre will compress the rim, ever so slightly making the spokes slacker. Higher the pressure, slacker the spokes. A clincher tyre is constantly wanting to 'pop off' the rim being that it's held on by the 'hooked' rim and the bead on the tyre. Not affecting the spokes.

I built Roxy's 3 lead 3 trail laced at the crosses and it's held up fine only needing a true after being mishandled in airports and polo. I also built a wheel for Rakan with a twist in the outside spokes of each group. Again with crosses and the single twist. I'm actually amazed at how true that wheel is after seeing it this past sunday!

I'm fairly sure I laced the second and last crossings as Alex said, the first one would be right on the hub. Maybe Roxy or Rakan/Zoe could post a pic?

I also remember when Alex was building his wheel mentioning the tension problem so when I built one I started with tension and then trued the wheel by loosening the spokes. Dunno if that's what helped or not though.

-

• #12

Hi Mike! Haven't seen you in ages! You've certainly got a good memory.

As for the tyre pressure thing, it might be a red herring, but this bike has odd handling anyway, it's got a slack seat angle and a tight head angle, short, very stiff, forks. anything that you change at the front end of the bike, you really feel it.

-

• #13

that wheel build must flex laterally quite a bit, more than i think i would like !

-

• #14

Hi Mike! Haven't seen you in ages! You've certainly got a good memory.

Not good, selective!

-

• #15

i built the same pattern and crossed ...the inside spokes under under over, the middle under,over,under and the outer over under over......and seemed all right it felt really stiff when you squeezed the flanges together much stiffer than 3 cross.....and it was a bit of a bitch to true becuz of so many crosses and was making really weird creaking when prestressed but once done it was really sturdy..........and it was a velocity deep v on dia compe high flange and halo black DB spokes

and no problem with the tyres or anything at all......i guess the truing was easy cuz the rim is deep section as -

• #16

Just rebuilt my front wheel going by this guide: http://www.baldurdash.org/OtherStuff/3leading3trailing.html

First time building and truing a wheel and it wasn't that difficult, just reused all the parts of the old wheel, getting a new wheel for another bike on Tuesday and am gonna do the same with that, though hopefully it'll be easier as it's all new parts, fingers crossed this one stays true for a good while, looks fantastic too!

-

• #17

Sorry, know this is an old thread but heres what the look of these type of wheels is on different hubs. Front is a small Shimano MTB hub and rear is a large flange on-one. Both are laced three leading three trailing with plain gauge spokes and Rigida Chrina rims.

The lacing pattern is as Roland Cooks excelent website

http://www.terminalvelocity.demon.co.uk/WheelBuild/If you are a fairly new wheel builder (like me) it took a couple of trues to get them to stay true as the spokes do have to settle down a bit. Now they are settled they fly. No problems with brake rubbing and the spoke tension has stayed good.

1 Attachment

-

• #19

Right folks, thinking about building up a 3 leading 3 trailing wheel for my rear wheel which uses a coaster brake. I've heard some people say that patterns like this wouldn't be suitable for disc brakes. Obviously the same would apply to hub/coaster brakes as they all rely on the spokes to carry the braking force. Although to me it would seem that 3 leading 3 trailing (assuming the spokes are crossed) should be just as strong as a 3x.

Opinions?

-

• #20

I've had no end of bother breaking spokes on my coaster. Let me know how you get on.

-

• #21

I've been riding mine for over a year now, i'd say putting about 8k miles on it and haven't had any problems with 3x. What spoke pattern have you been using?

-

• #22

mumble ahem 2 cross all head out on the drive-side mumble

-

• #23

Oh Skully...

-

• #24

Right folks, thinking about building up a 3 leading 3 trailing wheel for my rear wheel which uses a coaster brake. I've heard some people say that patterns like this wouldn't be suitable for disc brakes. Obviously the same would apply to hub/coaster brakes as they all rely on the spokes to carry the braking force. Although to me it would seem that 3 leading 3 trailing (assuming the spokes are crossed) should be just as strong as a 3x.

Opinions?

I cant see why this would be any different to 3x. The forces are theoretically more focused on certain areas of the rims. But I cant see this having a real world effect.

Skully.

Why would you use 2x all heads out on the drive side?

If its a dished wheel, then heads in would lessen this, plus it adds a little to the bracing angle. Although alternating probably puts the least stress on the spokes. -

• #25

the interlacing on a three cross improves rigidity. Give it a go at worst you will loose some spokes and a rim. If you can afford that do it.

crank

crank tynan

tynan BillB

BillB ChrisNW

ChrisNW Velocio

Velocio![Avatar for Mike[trampsparadise]](https://lfgss.microcosm.app/api/v1/files/234d264db96466e0e7aa35dd06b600d167573076.gif) Mike[trampsparadise]

Mike[trampsparadise] Dylan

Dylan mmccarthy

mmccarthy

number6

number6 Skülly

Skülly Smallfurry

Smallfurry TheBrick(Tommy)

TheBrick(Tommy)

OK, so this is a bit of an oddball thing to compare, but I built my commuting bike up with a 3 leading 3 trailing spoke pattern (as usual Sheldon has the answer if you don't know what I'm talking about http://sheldonbrown.com/org/iro/584/pages/06.htm).

This is a bit of an oddball build, but very pretty to look at. There are various variants on it. Sheldon shows no spokes crossed, I've seen all the spokes crossed. I read that with all the spokes crossed it's difficult to true. I tried to build it with no spokes crossed, but found it impossible to keep true after I de-stressed it during the build process, so compromised by crossing one set of spokes in each group like this:

This wheel held up for two years of daily commuting through all weathers, until I finally wore the rim out.

I never really worried too much about it, but I did notice that the bike handled very differently when the tyre pressure was a bit soft compared to pumped up hard.

When I rebuilt the wheel I used the same hub, rim and spokes (cheapskate!) and found that there were rub marks where the spokes crossed from the 3 leading 3 trailing pattern. So I guess the wheel had a bit of lateral flex after all.

As a conventional 3 cross wheel the ride is really noticeably harsher. The 3 cross build is definitely stiffer.

So, my guess is that 3 leading 3 trailing builds are better suited to a rear wheel than a front wheel and that this pattern might take some of the sting out of a build on deep section rims.