-

• #2

-

• #3

Tap gently all the way round, repeat until free. -

• #4

take it to rick or andy, if you;re not gonna need it they can always just trash it by drilling some holes and cutting the cup off.

Also a good idea is to tighten the cup into some jaws and get it off by spinning the frame....works a treat

hope that helps rup

-

• #5

Maybe a case of grannies and eggs (apologies in advance) but don't forget to turn it the correct way - easy if Italian, both sides unscrew the 'normal' way [anti-clockwise], if it's English, then the left side is 'normal', the right side is a left-hand thread so unscrews clockwise (English = left is right and right is left!)

-

• #6

My favorite technique is to arc weld an old bottom bracket spindle so its sticking out the side of the stuck cup. Then put a crank arm on the other end and then put that inside some scaffolding tubing or similar . The heat of the welding and the massive leverage satisfyingly undoes the most ancient rusted ,cross-threaded, knackered , cups .

Bring it round for a demo if you want -

• #7

get a biggger hammer

-

• #8

maybe a case of grannies and eggs (apologies in advance) but don't forget to turn it the correct way - easy if italian, both sides unscrew the 'normal' way [anti-clockwise], if it's english, then the left side is 'normal', the right side is a left-hand thread so unscrews clockwise (english = left is right and right is left!)

+1

also a good idea is to tighten the cup into some jaws and get it off by spinning the frame....works a treat

+1

-

• #9

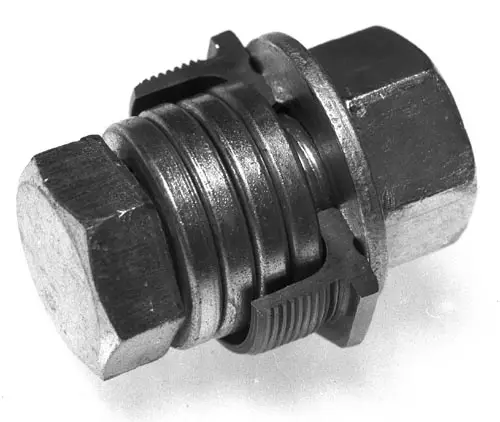

This simple method using a LARGE nut & bolt and some washers removed a very, very stuck bottom bracket for, just make sure the nut & bolt is as big as you can get to fit the BB shell and use plenty of leverage on the spanner (a length of scaff pole works great)

Courtesy of Sheldon Brown as ever, original page here: http://sheldonbrown.com/tooltips/bbcups.html

**Fixed Cup Tools **[INDENT]Very elaborate, expensive, and special tools are sold to bicycle shops for fixed-cup removal and installation, but they are not really necessary. A few cheap home remedies can do the job quite well. The first home remedy demands that you have a high-quality bench vise.Simply grab the fixed cup wrench flats in the vise jaws, making sure that you have good contact with all of the wrench flats' meager width. Grasp the bike frame and unscrew it from the cup. This technique works quite well.

If you don't have a bench vise, or if the vise technique happens to not work well on your bike, you can make a universal fixed cup tool for less than a dollar (assuming you have access to a couple of large wrenches).

The tool is an imitation of a $40 shop tool that fits into the fixed cup as a crank spindle would, and pinches the cup. You apply unscrewing force to the tool, and it transfers this force to the cup with this tight friction fit.

The tool consists of a large bolt, a nu tor two, and a few washers. The size of the bolt is not particularly critical, as long as the bolt is strong enough not to break, but small enough to fit through the hole in the cup. I used to use an ordinary 1/2-inch, 13 tpi hex bolt (also called a "capscrew"), which served me well for quitea while. It finally met its match on afriend's Schwinn that had an unusually tight fixed cup; the bolt snapped in two before I could remove the cup.

Now I use a 5/8-inch 18 tpi hex bolt 1 1/2inches long, with a nut, a flat washer, and four lockwashers. The 5/8-inch size is the largest standard size that will fit through the hole in the cup. This bolt and nut both take a 5/16-inch wrench. With my 1/2 inch drive Craftsman six-point socket set, the 15/16-inch socket is also the largest size that will fit into a normal bottom bracket shell.

If you have some other brand of socket, check the fit before you buy the bolt and nut-you might need the next size down (9/16-inch).[/INDENT]

Home-made tool shown in cutaway bottom bracket cup.**Nut on the Outside** [INDENT]The bolt is put through the cup fromthe inside of the bottom bracket, and the nut screws onto it from the outside. There should be washers on both sides of the cup. You will need a socket wrench anda short extension to tighten the bolt from inside the bottom bracket, and a box wrench for the nut. A large socket wrench will not fit into the cup, so you will need some small diameter washers to space the head ofthe bolt out so that the socket wrench can reach it. This is what I use the four split lockwashers for. I didn't need lock-washers as such, but the readily available flat washers were too large in outside diameter to fit into the cup.To remove a right threaded fixed cup (French or Italian), tighten the bolt with the socket wrench from the inside of the bottom bracket, holding the nut with the box wrench. Once the bolt is as tight as can be, keep on tightening it, until the cup screws itself out. Once the cup starts to move, turn both wrenches together.

To remove a left threaded (British or Swiss) fixed cup, hold the bolt with the socket wrench and turn the nut with the box wrench.

Use the same tool the opposite way to install the new fixed cup.

You might worry about damaging the cup, but this is not likely to happen. The washer doesn't usually come into contact with the bearing surface. Even if it did, bearing cups are made of extraordinarily hard, heat-treated steel, much stronger than that used to make washers.

[/INDENT] -

• #10

^Effectively a pikey-tech home brew version of a tool all good bike shops should have. If that method doesn't work, try your lbs.

-

• #11

iv tried all above techniques except asseens welding idea and the pikey bodge job, both of which ill try over the week end.

-

• #12

i just got mine of with the jaw thing, the frame gives pretty good leverage, you sure it is a threaded cup?

-

• #13

This is one of those things that, if you don't have a vice, it's better just going to the LBS - they'll have all manor of weird and wonderful tools made just for it and it'll never cost more than a fiver - worth it to keep the knuckles blood free!

-

• #14

fortunately between work and home i have 3 workshops to use and there all pretty well equipped, but i got the cup out in the end by cutting 2 small slots in the cup the i bashed a piece of steel bar in to the slots, clamped that into a vice and it came out nice and easy.

-

• #15

fortunately between work and home i have 3 workshops to use and there all pretty well equipped, but i got the cup out in the end by cutting 2 small slots in the cup the i bashed a piece of steel bar in to the slots, clamped that into a vice and it came out nice and easy.

HURAAAYY!

another happy ending to a thread

-

• #16

sorry for lazarusing this thread.

does anyone have one of these wonder tools? offer me a price on how much an lbs would charge on removing said cup? and/or seized headset?

i know, i know, ring said LBS. -

• #17

My local said 15 quid - sounds like a rip off to me. Might try the smaller/friendlier/slightly further away one if I can't bodge it out at the weekend.

-

• #18

15 quid is about the minimum hourly rate. i think that's well priced. but then i am a [FONT=Arial]naïf.[/FONT]

-

• #19

This is one of those things that, if you don't have a vice, it's better just going to the LBS - they'll have all manor of weird and wonderful tools made just for it and it'll never cost more than a fiver - worth it to keep the knuckles blood free!

Motherfcukers @ Evans quoted me £12.50, but I need the bb out quickly and don't have time to mess around :O(

-

• #20

Not a bad price concidering what's involved.

-

• #21

Seems fair to me. Cycle Surgery quoted me a bit more £15 or £20 but then charged me less bc they used a vice and it came out easily.

Remember they do have overheads.

Getafix

Getafix andy.w

andy.w eddie

eddie retrodicorsa

retrodicorsa RV’s-Balls

RV’s-Balls dicki

dicki Seeds

Seeds Dangeruss

Dangeruss randombadger69

randombadger69 rupert

rupert Fruit

Fruit machineisbored

machineisbored beanpie

beanpie Donut!

Donut! hugo7

hugo7

im doing up a old beater for a friend (its my old hack) it needs a new BB but im thinking cartridge will be better than a cup and spindle job, only problem is i cant get one of the cups out. this was the case when i re painted it the first time so i just left it any advise on how i can budge it?