-

• #2

I decided a while a go I could have a kick by trying to built my own bag. After too much wasting at

a lot of levels I came up with something very standard, much helped by my gf.... and I really think

it´s worth to give it a try. Opinions would be appreciated.

yeah ive been doing the same, made a couple last week, theyve turned out alright.

this site has a really got pattern http://eeio.blogspot.com/2004/12/recycled-banner-golden-mean-messenger.html real easywhere did you get your material/what did you use? ive just been using stolen vinyl banner

Yes, this was the 1st tutorial I saw of how to do it really easy, but after trying this method I just didn´t like the final shape.

My pattern was taken from a messenger bag from NorthFace... it is really versatile room wise. No padding just because it fits perfect on my shoulder. That tutorial BTW is related to this vid

YouTube - Make a Messenger Bag Out of Trash Bags!

I got my materials (cordura mainly) from Portugal, at some deparment store, rug and mats section. €3 a meter for the cordura. On the bay is really expensive. All the buckles, straps and velcros from Klein's, soho.

the tape is 3M scotchlite, on the bay is quite cheap, well it´s never cheap actually.

Is it self adhesive tape or stitchable fabric?

stichvkjvsble fabric

If you want reflective fabric, try this place... http://www.profabrics.co.uk/index.php

Scotchlite fabric here... http://www.profabrics.co.uk/shop/show_product_info.php?id=RS1scott where do you rekon a good place for buckles is? ive looked in all the fabcric and sewing shops here in brighton and they don't seem to have any idea?

pro-fabrics/pointnorth have buckles etc - and ITW-nexus do a free sample program (although not sure if to the uk)

One thing I am still looking for is a supplier of truck/pvc tarp - seemingly impossible to get hold of in this country by the meter....

Ace supplies is the BEST place in the UK for buckles...they also do rip-fast velcro, and different kinds of webbing...i get most of my supplies from them.their service is fantastic...really fast....no minimum order quantities either.

Nexus sample thing is a waste of time...they take ages to get them to you, far easier to go to Ace supplies.

Which is the problem with Cordura also...most places don't want to sell per meter...and at over £200 per roll for liner fabric it's pretty bloody expensive.

How much tarp are you after and what colour?Cordura doesnt seem too bad - seems to crop up on ebay every so often - managed to get (just) enough for a bag for £5! (1000d)

dont care what colour it is - after about 2m i guess (presuming it comes on 1.5m wide rolls) - only problem is im not in London - out West in Bristol :)

Well for the moment anyway I have cut up an old inflatable mattress - the fabric is pretty tough it would seem and is certainly waterproof :)

Thanks for the heads up on ACE they seem cool - although at this rate its going to be a long time before I want to make another bag. I am only making this one as my "prototype" is too small really and looks like crap :)

aha looks like kayospruce do 620gsm PVC tarp: http://www.sailcloth.co.uk/content/products/Marine_and_Technical/PVC_Materials_index.htm not too bad a price either - delivery is a bit killer tho

which makes me think actually - maybe sailyards/yachting supply shops maybe a good place to look locally......

Actually i might have a bash going to a sign makers in hereford and seeing if they have any offcut i could use to have a practice sewing on and then making a liner. . .

If you want offcuts, the best place is a bouncy castle factory.

ladies, forget truck wrap... The vinyl signs u see everywhere, everyday, are made out of the same fabric/component. I was using that back in Portugal, doing stuff like Freitag. And plus, it´s easier to sew. Just ask around.

It's not always the same stuff.

That's like saying a colnago is made from the same stuff as a raleigh mustang.

The base fabric can be different...either polyester or nylon...it can be a different strength weave too.

The PVC coating also varies in thickness and quality and also comes in different finishes which can affect the suppleness of the finished fabric.

That's why different companies state different weights for their liners.

Truck tarp sidings are usually far heavier weight than a lot of bag companies use...for example, chrome liners are thinner than reload liners.

That's why the sign fabrics are usually easier to sew.If u looking for some diy easy to do, easy to sew, truck tarp is just mental, no home sewing machine would take that kind of beating. I know, I broke a brand new SINGER! (luckily from argos... so they changed).. all to do with the amount of pressure on the stitching. I think you scott are ahead of 99% of the rest of us when it comes to this business... I´m trying to have people NOT doing my mistakes. Think modest, achieve big.

I fully agree...if you want to make proper, strong, long lasting bags you need the proper kind of machine.

I'm just giving people info on where to get the proper materials to make a long lasting bag...but as you say, if you don't have a machine that's up to the job, then you're gonna have to sacrifice the longevity of the bag a little by using thinner fabrics.

One thing worth noting though is that a regular sewing machine can still get through fairly thick layers so long as you use the thickest needles you can fit in the foot, and 'walk' the needles through really thick parts by hand.so what kind of machine do use scott? i've been sewing everything i do by hand as i'm scared of these machines, might invest though, would want something strong for the long term..

most modern home machines are plasticy crap - better off getting an old basic machine with a decent motor or if you have room an industrial machine.....

plenty of decent old machines around for cheap - I picked up my Husqvarna off freecycle...

I use a seiko twin needlebar knockout walking foot industrial machine.

I'm actually selling my seiko single needle industrial machine at the moment....go check it out in the classifieds.Perfect for all you budding bag makers. :)

SINGER 4220

I used this (broke one as well!), it´s my gf´s, she´s doing fashion design. It works fine with the sort of materials I was using, but getting to the straps u start feeling it´s all too dodgy. EVE with heavy duty Brothers it can go wrong.... i must be the biggest murderer when it comes to sewing machines.

managed to find some bright orange tarpaulin at the local market for £3 a meter (only 1m wide tho)

1.5x1m seems to weigh about 1kg so seems reasonably tough...I think anyone who hasnt made a bag completely underestimates the amount of work involved in making one. What is in theory a simple pattern becomes vastly more complex when you start having to add pockets/ webbing/ padding/ straps etc etc along with having to seal seams, hem and bind the edges...

Reckon that I have already spent 24hrs on this bag and its only half done....

obv I aint a pro and am therefore slow - but if you are custom making bags then you cant assembly line alot of the work anyway so its still gotta be pretty slow going

keep up the good work DIYers!

Keep up with the good bags scott, maybe one of us will be able to get on this list in a few years :O i can now only just try and understand the work that goes into your bags! i can see why it takes so long, do you mind me asking how many hours it roughly takes you to make one? (say, a marlon?)

just drawn out, cut out and sewn up my first pattern on a scrap sign (not tarp, bit stiff).

it fucking works, so happy.

just waiting for cordura, straps and clips to arrive today or tomorrow.

everyone do this, it's fun and challenging, and you get a custom bag a the end of it.

ok here are some camera phone pics.

This is the first bag i've made (not even a bag or finished yet).

I had this old vinyl sign which i thought i'd use as a liner but in reality it is way too stiff, so i've used it to practice my bag pattern and see if my sewing machine is up to the task.

It turns out, the pattern is great, and the sewing machine is fine (with normal thread, we'll see how it handles hardcore nylon stuff tomorrow).

here's a pic of the bag open

pic of bag shut

pic of simple strap arrangement (not final arrangement)

pic of pattern dimensions, i found it really useful to have the pattern fully drawn out on the outside of the liner

here is the template i made, i liked the bags made by zugster, pac and various other companies so made my pattern combining certain features from many brands...

so very early stages, as i said, it wont look anything like that when finished as it shouldn't stand up like that, the material is much too stiff. but it's just to see if the pattern worked and it does.

I'm going to make mine with full cordura outer and a packcloth liner on the inside so it will be a three layer construction. also i planned on sewing all three layers together like a pac but i'm starting to think my machine might not make it through all that material, especially when doubled over. so i'm going for a floating liner, as this will be easier on my machine, if a little bit more work.

also remember to add half an inch on the pattern to sew it up!

edit: cordura just arrived!

p.s. there is LOADS of info online about making bags, google it and you will find all the information i've used. but i wouldn't just copy the bags they've made, most of the instructionals produce pretty plain, boring, featureless bags. I just used the sites to help me figure out a pattern and how to sew it up, then i went to the pac website and zugster to see about strap arrangements, suspension strapping etc. so hopefully i will be able to make a really useful bag to work with.

Whoa dude, well done, congratulations! I think a floating liner will make you happier if you ever get caught in the rain, assuming you fix it to the exterior with the least seams possible... my bagaboo has a floating liner but water still managed to get in two weeks ago when it rained a lot. The cordura shell got soaked and water got through the seams where the liner is fixed to the cordura exterior!

thanks, yeh i'm just connecting the liner to the outer around the flap and with velcro around the front of the bag, like a chrome. so you can remove the liner if you need.

also trying to figure out how to sew in a secret pocket. mindfuck

I have new-found respect for the DIYers, I tried it today and all I managed was a wonky liner with lots of holes in it and several tantrums. Despite being under the guidance of a master bag-maker.

This revelation that I suck at bag-making has sadly meant I am being forced to rethink my plans to launch a rival bag company from Grobag Towers.

Right, finished.

that was fucking torture. so much to think about, i've left a few features off the bag as i just couldn't handle it any longer. was going to have many internal pockets and a lock pocket on the outside.

very happy with it though. the size is great, it works, it fits perfectly, the load is even, the padding is nice. hopefully my next one will be a lot neater.

i began to feel the limits of the machine though, not the power, more the maneuverability of the bag in and around the needle. having the machine sunk to the same level as your work surface would make it a lot easier to sew straight in certain areas, i think.

(click through for more pictures)

now i can spend this week making wallets and tool pouches from the scrap vinyl and cordura. might get bored of this colour scheme though.

Wow, great job for a first bag, I'm seriously impressed.

good work, looks very neat

seriously nice snoops! im being inspired! i may actually make one in the distant future!

Well done snoops. looks good.

One thing to remember is that if your buckles aren't tucked into seams then it's worth doing a flag stitch on the webbing to attach them.

Apologies if you already did, but from the pic it looks like a single line of stitching.

The second bag will be far easier. :)thanks for compliments, i can only see the imperfections in it though. and because i know i made it, i presume it's going to fail all the time. but there really isn't any reason why it should.

scott don't really know what a flag stitch is? not up on the terminology, i stitched a square with a cross in. that a flag?

and scott, i found it really, really hard sewing on the binding (the black trim).

any advice? is it just hard with one piece bags?

Yeah that's a flag stitch...you'll be fine then. :)

Edging the bags is the bit i hate the most...it's always a bitch...and the more layers you have from having pockets too, the harder it is...it always tries to slip off.

You'll get used to it the more you make. I'm really fussy about things being right though, so i take my time on the edging...some people don't however....see below!

Also, check your bobbins before edging...there's no excuse for joins in the stitching when you're edging in my opinion.

you mean always make sure there is enough in the bottom bobbin so you can ensure you will make it round in one swoop?

yeah. looks horrible when there's joins all over like that pouch above.

Here's another example of bad edging....

There's no need for the corners to be so ugly...and these are bags for sale on a website.

If a job's worth doing, it's worth doing well.how would you do 90 degree corners? i managed to do curved edges, just.

you tuck the edging into a 45 deg angle. You basically stitch to right at the end of the straight, lift the needle, turn the fabric and binding, then tuck the corner into a neat 45 deg fold before putting the needle back in, but you have to do it without pulling the threads to far.

Basically you don't just let it form a lumpy old mess on the corners. :)

Practise edging on scrap fabric till you suss corners.cheer scott.

did you mean seamed? [sorry]

and no, not in the textiles industry. i just had a lot of time on my hands this weekend and my old bag ripped. so i made a new one.

i did enjoy making it though, really tested my perseverance. it's nice to give yourself a project every now and then.

and i don't think this does need a new 'thread', it's good to have a list of bags for people to buy, and then some advice on how to make one if you are so inclined.

pretty much finished mine over the weekend too - although I forgot to take any pics during the process, also I am not 100% sure on the flap pattern I have used - edging it was even more of a bitch than it need be...

will stick some pics up this evening :)

love this thread now.

ou only love it because you are getting lots of (well deserved) praise!

good work tho Snoops, im gonna have to step my game up on my next attempt!haha yeh but i want more people to post there stuff, DIY 4 EVA

snoops, how much you will say as been the cost of that bag? just materials

hard to say, i was very kindly given the vinyl, and i couldn't find it for sale anywhere else so i'm not sure how much the whole bag should have cost me in materials.

the straps and buckles cost between 7 and £14 per bag i think, depending on what you go for (and what quantity you buy in, as if you buy hundreds of buckles they work out at say 10p each instead of 50p each if you buy 10). cordura is around 10-15 quid a meter i think. i used around 3 metres. as i said not sure about the cost of vinyl as i found it unobtainable.

those prices are shop prices, you can find it all cheaper.

(scott correct me if any of this is wrong, i'm no expert)

certainly sounds similar to what I have paid/spent

recon about £40min for a medium sized bag - thats with "some" but not a lot of fabric/webbing etc left over.

heres the (really crappy) pics,

pretty satisfied with it (for the mo) though give it a couple of months and the bug will bite again and I will be wanting to make another...

There is some PALS webbing on the bottom for attaching extra straps/lights etc - think on the next one I will include some on the inside and the outside of the flap - just so time consuming bartacking every inch....

nice one danb, are those side compression straps? and what did you use for the back padding and shoulder strap?

(i can't see your flickr photos, i don't have permission)

also what thread did you use? what machine did you use? and is it a one piece pattern, i can't quite tell?

thanks, yeah - 6 compression straps - 2 at the bottom 4 on the sides.

Used an old camping rollmat for back and shoulder padding

Thread is v69 dabond polyester sail thread - it is a one piece pattern, although more complicated than it need be really...Oh and the machine I used was a 60's Husqvarna - pretty much all metal construction - must weigh like at least 20kg... its certainly a lot heavier than the old singer i had

Wow, Dan, Snoops, such good work for a first bag. Keep it up!

Cheers,

First proper test run in with the bag this morning - has held up nicely, very comfortable and great being able to really cinch down all the compression straps to get it to the best shape.

Just a shame it didnt rain (!!??)Good job Dan...looks a lot like a project tortoise.

I'm liking seeing people making bags for themselves...you get a great sense of achievment when you finally finish them.

Either of you planning on making them to sell?danb where did you source that buckle for your strap? looks like the ones on a Chrome bag?

yeah - the one peice im not that happy about - ridiculously heavy and needs an extra ladderlock for adjustment.

Its from a belt btw - off ebay - like this one but a uk seller and was about £3 or £4: http://cgi.ebay.co.uk/Official-FORD-MUSTANG-SEAT-BELT-Belt-Buckle_W0QQitemZ270447040997QQcmdZViewItemQQptZLH_DefaultDomain_0?hash=item3ef7e659e5&_trksid=p3286.c0.m14

I do not think there is anyone doing what you describe (from a top corner to the opposite bottom corner). I don't know whether that's because the bag would be unstable or whether it's never been tried. In practice I suspect you could not tighten the strap and keep the bag stable at the same time, but I haven't made a bag yet ;)

There are no messenger bags that have the strap going from top corner to bottom corner, because if it did then the bag would simply flip over on your back as the weight would all be above the strap that goes under your arm, and as a bag works by tightening until it reaches your neck and your armpit you'd end up with a bag against the back of your head.

haha - yeah good point Scott, hadn't thought about the twisting, just thought that it would end up too high like you say.

yeh i found strap positioning quite hard to decide on. on the practice bag i made i ttried a few positions, too low and it feels like it wants to flip over as scott says, and too high and the weight of the load is felt much more on your lower back. when you get it right the load seems to sit perched around your shoulder blades making it much more comfortable. i think the compression strap system helps a lot too.

not really thinking about selling them at the moment, i'm giving one to a mate who's a courier to keep and test, and make sure they don't fail. i just wanted to be able to make them really. I'll make a few for friends and family, then if people want one, i wont say no. but i really need to clean up my stitching, i wouldn't feel comfortable selling someone this bag with the stray threads and wavy stitching in places.

Cheers,

Incase anyone else fancies a go here are a few useful links to get you started.

Good guide to bag making here: http://leiflabs.blogspot.com/

Parachute riggers handbook - lots of good info on sewing strong seams etc: http://www.faa.gov/library/manuals/aircraft/media/FAA-H-8083-17.pdf

Macho sewing site (need to sign up to see content - watch out, lots of guns and overweight men with silly holsters) : http://www.diytactical.com/forums/index.php?board=40.0

Supplies:

http://www.profabrics.co.uk/snap_product_search.php?search=true&category=Fabrics

http://www.acesupplies.co.uk/

http://www.sailcloth.co.uk/index.htmawesome danb, parachute riggers handbook is just the kind of thing i was looking for.

yeah - its total overkill for most applications but still a very useful book

overkill is what i'm going for!

taking over - great album

Is it some extra flap at the sides that I see? I mean, in the last photo it looks like the flap is wider that the bag... I sometimes thought it might be a good move to keep the whole sides covered up and more waterproof.

Why did nobody else think of that? ;)

Postie bags seem to follow that design, why it is not used on messenger bags I dunno ;)

I was joking...the good ones already have covered sides. :)

Ok. Done it for you. Continue.

Scott will be referee.

-

• #3

I remember that freightbaggage backpacks used to come with external flaps like postie bags, but they have now been redesigned. I'd like to ask to you bagmakers, I would have thought that external flaps prevent water from seeping under the flap and protect the external pockets more that internal flaps (which seal the main compartment very well though). Since I had water seeping in through the side stitch where the floating liner is attached to the shell I would like to have some way of getting the flap to cover the area to protect it! Mind you, the seepage only happened because the exterior cordura was totally soaked.

-

• #5

I remember that freightbaggage backpacks used to come with external flaps like postie bags, but they have now been redesigned. I'd like to ask to you bagmakers, I would have thought that external flaps prevent water from seeping under the flap and protect the external pockets more that internal flaps (which seal the main compartment very well though). Since I had water seeping in through the side stitch where the floating liner is attached to the shell I would like to have some way of getting the flap to cover the area to protect it! Mind you, the seepage only happened because the exterior cordura was totally soaked.

Not entirely sure what you are getting at - is this an extra top flap?

Or just raised sides (like Scott's Grobags?)

Also the whole point with a floating liner is that it is only attached around the opening rim of the bag - otherwise as you say water will wick up through the threads and into the bag. Due to the positioning of the flap edges (where the inner is attached) when they are folded over - there shouldnt ever be any part of it where it could get through....Perhaps some pics/links to examples might help?

-

• #6

also worth having a browse through this

http://www.bikeforums.net/showthread.php?t=191577&highlight=custom+bags -

• #7

Not entirely sure what you are getting at - is this an extra top flap?

Or just raised sides (like Scott's Grobags?)

Also the whole point with a floating liner is that it is only attached around the opening rim of the bag - otherwise as you say water will wick up through the threads and into the bag. Due to the positioning of the flap edges (where the inner is attached) when they are folded over - there shouldnt ever be any part of it where it could get through....Perhaps some pics/links to examples might help?

What I mean for external flaps is something like the bags used by posties:

http://www.michaellinnell.co.uk/index.php?p=showprod&id=448&cat=Satchels%20and%20Trays

where the flap bends over and keeps close to the sides of the bag. I realise that a flap like that might not be wider than the flap of a messenger bag, just shaped different. I also do not know how well it works. One thing I notice in my bag, a bagaboo workhorse which has the corners of the bag attached to the strap, on the right corner, the one on my hip when wearing the bag, the flap get tightly against the bag when I tighten the strap, while the left corner on my shoulder does not do that, leaving the side more exposed.

About the liner, my bag has a liner that floats off the bottom of the bag, but it is attached for half the length of the side to the top of the bag. Semi-floating then?

-

• #8

Ah I think I see what you mean - looks like the corners are darted so that it curves around the bag...

Don't think that would work too well with compression straps etc - as they change the depth of the bag. Also with suspension strapping on the top - this should pull the flap round the corner avoiding it, so shouldnt be neccessary.Might be worth picking up some seam sealant (tent shops sell it) to use on your bags seams - should help prevent water getting through (although it will wear off eventually)

-

• #9

made a proto of my bag a couple of days ago - Am going to start on the reall thang today. I'm gonna use some heavy waxed cotton for the structure, and sign material for the liner. My plan is to divide the main section in half, aving one section closed by the flap, and the other section having a roll-top with a buckles like a sailing or kayaking bag - will keep whatever's inside dry underwater if I get the seam sealing right. Any tips?

-

• #10

sounds interesting alfie, i'm going to make a wax cotton bag when i'm better with the machine.

i don't know anything about seam sealing but would be interested to hear how you get on...

-

• #11

Ah I think I see what you mean - looks like the corners are darted so that it curves around the bag...

Don't think that would work too well with compression straps etc - as they change the depth of the bag. Also with suspension strapping on the top - this should pull the flap round the corner avoiding it, so shouldnt be neccessary.Might be worth picking up some seam sealant (tent shops sell it) to use on your bags seams - should help prevent water getting through (although it will wear off eventually)

The suspension strapping does pull the flap a bit around the top corner, but nowhere as much as for the bottom corner in all cases I have seen (i.e. my bag and other people's bags I had a look at while waiting at lights). In fact I think project tortoise bags had the webbing attached to the flap on the top corner to pull the flap closer to the bag. What I can say is, on my bag, which has suspension strapping, I wish the flap got much closer to the bag when I tighten the straps.

Ta for the sealant suggestion... I'll probably have a go, though water ingress happened only once in 2 years, and under the very very worst rain I had to go through (I know I'm retentive, but I like my stuff to stay dry in all conditions ;)).

-

• #12

<3 you guys! ok finally got some spare cash :D time to start thinking about a bag, and then designing it! hmmm danb your bag is fantastic, the parachute riggers handbook looks tres interresant! i shall be definatley having a good look at that! thanks again GA2G! great work. . .

-

• #13

Nothing to do with me rocker9455. Its will be all about the guys and gals on here that can make the effort, and Scott will be by from time to time to send them in the right direction (I hope).

I'm an OTP kind of person, but I do admire those that are creative. Interesting also to see the photos of the results. Really good so far.

-

• #14

For those of you without the resources/money/access to tarp and water-proof materials for bag making, what about buying a couple of IKEA bags, £1 each and big enough to cut up and get enough material for the lining/outer of a large messenger bag. It could work maybe? Even if the material was doubled up for extra piece of mind. I've been using IKEA bags for heavy items and laundry and in two years I've not had any of the bags degrade or break. Even the handles could be recycled as they are surprisingly strong.

IKEA's started doing smaller versions of the big blue bags now, so possible pannier bag liners?

I don't make bags, so if the suggestion is cack, sorry!

Can I bump this post to this thread?

I've started to use the large bag to line my sports holdall, it works a treat especially for containing my sweaty gi and keeping everything else in the bag dry and smell-free but also as the holdall isn't waterproof, it keeps a clean gi dry (the weather has been horrendous lately). I haven't made my bag from scratch but I'm certainly trying to improve on it to fit what I need them for. My next stop is to stitch a zip onto the Iiner and secure the liner into the bag permanently.

-

• #15

Zips generally (unless you buy very expensive ones) arent very waterproof - perhaps a roll top closure for the liner might be better - also - any stiching introduces holes into the liner which then allows water through... all things to consider.

Also I havent tried it but I can imaging that the material used for those Ikea bags is a complete pain in the arse to work with - given its "crunchy" nature....

-

• #16

danb, snoops, nuknow,

How are you guys getting on with your DIY bags? I'm never going to make my own, but I'm curious about the processes.

Any problems with the bags?

Any more made?

More photos?

Anyone ready to make bags for others yet? [GroBags Towers waiting list, still interminably lengthy]

-

• #17

hey ga2g

yep still making, my first prototype is still going strong, i still use it for big hauls (wheels and groceries mostly).

I have made a second prototype, simplified the design, i made it with a new industrial machine that i bought off Scott.

Here is my Flickr - http://www.flickr.com/photos/39995871@N07/

I am making bags for others, i am just finalising a name and logo, then i will post my blog here. I have had a few people express interest but if you would like a bag just pm me.

-

• #18

yeah mines all finished - just about working up the courage to start another soon I reckon :)

Pretty pleased with the size/shape of mine but have a few things I want to change - mostly to do with the straps and padding.

Will try and take some more photos outside and in use.

-

• #19

Still in full mode. Know now where to (re)enforce the stitching, nothing serious, just more comfort.

Totally DIY, Scott´s are the only bag I would buy, besides not having dough I rather like the process

of creating your own style. -

• #20

You guys ever thought of collaborating? I can see good features that are different in each of your efforts. Seems to me, that you might make up bags together, collaborating in the design and manufacturing process, till you are each benefitting from the work. Just an idea, which could only be plausible, dependent on geographic positioning, and whether you wish to have someone else critique your ideas.

I feel stupid suggesting it, because I'm so not a hands-on person. Anyway, as you were. :)

EDIT: Then when you've gained enough from each other, you show your own individual styles?

Sorry if I'm out of line, but I am just extremely enthused by what you've each done so far. -

• #21

Shit, i drank too much to collaborate...

-

• #22

Really, it should be Scott on here giving the encouragement, but I think he's had enough of

me/us/Beth Ditto, so he's scarpered to a better place. :(So, I'm going to be bold, and say what I like about each of the bags you guys have done so far, and the things that maybe I wouldn't want as much.

danb, I love the look, shape, and especially the texture (judging from the photo of course) of your bag. I'd gladly have one like that. The strap arrangement looks narrow though, for a big guy like me. I was also wondering, if having the strap points closer together would make the bag swing more, or less, from side to side when cycling. From the set-up, it looks like you have a stabilising strap? If so, super!

snoops, I love yours. It looks professional and polished. Amazing for a first effort. Would you be doing left and right shoulder versions? Also, what about colour options? You should inculde some of your other Flickr photos on this thread, as not everyone wants to go to another site just to see the back of your bag.

nuknow, I like your visualisation the best maybe. Its practical for winter, bright, and fun. The reflective strips are excellent. From my 17-18 year experience with my Timbuk2, I have a feeling, that without a stabilising strap, your bag would slip alot from my shoulders. That would be my main recommendation. Hope you don't mind.

Keep up the really excellent work fellas.

-

• #23

I do agree with you on that bit of the strap... need to work that out, however, experience has showed me that when full it doesn´t slip out of your shoulder, the shape helps it to stay in place.

I will be coming back to this project very soon, I need my GF to be on it as well, she does most of the sewing, I´m the design manager ;-) -

• #24

I'm hoping to make all my bags custom to the buyer. So you can have it whatever shoulder swing you want, with whatever features you want, internal or external pockets wherever you want them...

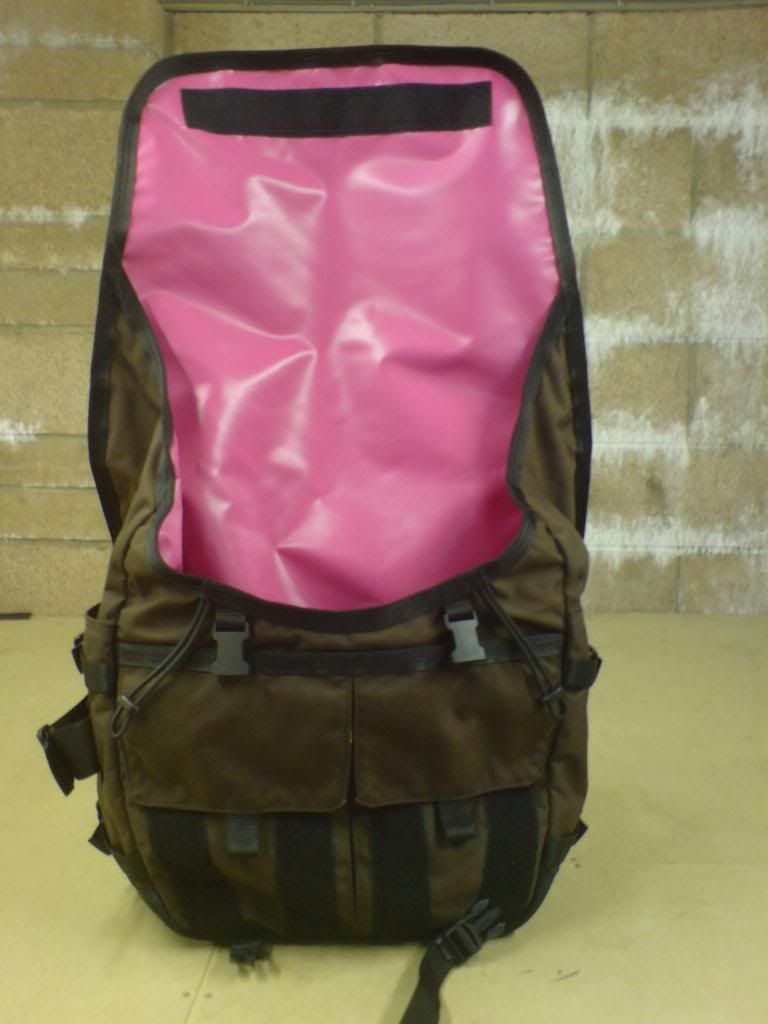

The basic bag will be like this (pictures are of a prototype, a few revisions to be made to the flap width and strap placement)

This will cost around £100. Then any features you want add to the cost, as the more features, the more materials and time it takes to make.

Extra features include:

-Flap clips or second shoulder strap

-Suspension strapping

-3d front pocket

-Compression straps

-Split strap and phone pouch

In addition to bags I will be making some accessories:

A strap pad that can be added to bags which don't have one

(this one has a phone pouch attached)

(this one has a phone pouch attached)A lock holster that develops on the fabric horse design by incorporating a key clip to save your belt loops

key clip

inner tube pouches

and hopefully I will have my hip pouch pattern finalised

(I'm not happy with the shape of this one)

(I'm not happy with the shape of this one)Basically I'm just learning how to sew and I am really enjoying it, I will have a website/blog up and running soon where I will post my progress. Sorry for such a long post.

p.s. my stitching is actually good now...

trying to decide between these two logos/names

carrier or belk?

-

• #25

It's looking good!

I like the pidegon with carrier underneath

GA2G

GA2G

mattty

mattty danb

danb 31trum

31trum Alfie

Alfie snoops

snoops rocker9455

rocker9455 Concrete_Island

Concrete_Island nuknow

nuknow

Ed was right. Post here so anyone wanting to learn, will stay on topic, and have a chance of comparing specific knowledge with others.

All those who posted in the bag list, simply open that thread and this one at the same time (different tags, pages or browsers) and copy-and-paste here. So far, some of you guy are doing really impressive work! Maybe Scott will give you a job? :)