This simple method using a LARGE nut & bolt and some washers removed a very, very stuck bottom bracket for, just make sure the nut & bolt is as big as you can get to fit the BB shell and use plenty of leverage on the spanner (a length of scaff pole works great)

[INDENT]Very elaborate, expensive, and special tools are sold to bicycle shops for fixed-cup removal and installation, but they are not really necessary. A few cheap home remedies can do the job quite well. The first home remedy demands that you have a high-quality bench vise.Simply grab the fixed cup wrench flats in the vise jaws, making sure that you have good contact with all of the wrench flats' meager width. Grasp the bike frame and unscrew it from the cup. This technique works quite well.

If you don't have a bench vise, or if the vise technique happens to not work well on your bike, you can make a universal fixed cup tool for less than a dollar (assuming you have access to a couple of large wrenches).

The tool is an imitation of a $40 shop tool that fits into the fixed cup as a crank spindle would, and pinches the cup. You apply unscrewing force to the tool, and it transfers this force to the cup with this tight friction fit.

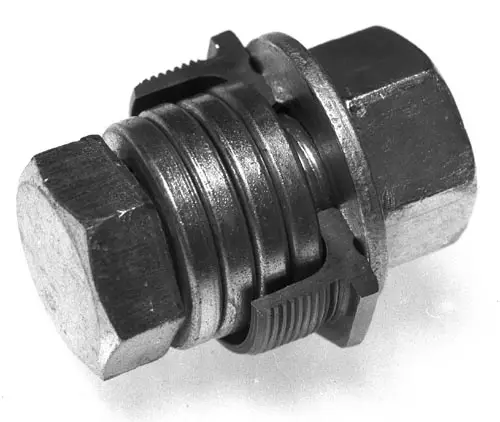

The tool consists of a large bolt, a nu tor two, and a few washers. The size of the bolt is not particularly critical, as long as the bolt is strong enough not to break, but small enough to fit through the hole in the cup. I used to use an ordinary 1/2-inch, 13 tpi hex bolt (also called a "capscrew"), which served me well for quitea while. It finally met its match on afriend's Schwinn that had an unusually tight fixed cup; the bolt snapped in two before I could remove the cup.

Now I use a 5/8-inch 18 tpi hex bolt 1 1/2inches long, with a nut, a flat washer, and four lockwashers. The 5/8-inch size is the largest standard size that will fit through the hole in the cup. This bolt and nut both take a 5/16-inch wrench. With my 1/2 inch drive Craftsman six-point socket set, the 15/16-inch socket is also the largest size that will fit into a normal bottom bracket shell.

If you have some other brand of socket, check the fit before you buy the bolt and nut-you might need the next size down (9/16-inch).

[/INDENT]

Home-made tool shown in cutaway bottom bracket cup.

**Nut on the Outside**

[INDENT]The bolt is put through the cup fromthe inside of the bottom bracket, and the nut screws onto it from the outside. There should be washers on both sides of the cup. You will need a socket wrench anda short extension to tighten the bolt from inside the bottom bracket, and a box wrench for the nut. A large socket wrench will not fit into the cup, so you will need some small diameter washers to space the head ofthe bolt out so that the socket wrench can reach it. This is what I use the four split lockwashers for. I didn't need lock-washers as such, but the readily available flat washers were too large in outside diameter to fit into the cup.

To remove a right threaded fixed cup (French or Italian), tighten the bolt with the socket wrench from the inside of the bottom bracket, holding the nut with the box wrench. Once the bolt is as tight as can be, keep on tightening it, until the cup screws itself out. Once the cup starts to move, turn both wrenches together.

To remove a left threaded (British or Swiss) fixed cup, hold the bolt with the socket wrench and turn the nut with the box wrench.

Use the same tool the opposite way to install the new fixed cup.

You might worry about damaging the cup, but this is not likely to happen. The washer doesn't usually come into contact with the bearing surface. Even if it did, bearing cups are made of extraordinarily hard, heat-treated steel, much stronger than that used to make washers.

[/INDENT]

This simple method using a LARGE nut & bolt and some washers removed a very, very stuck bottom bracket for, just make sure the nut & bolt is as big as you can get to fit the BB shell and use plenty of leverage on the spanner (a length of scaff pole works great)

Courtesy of Sheldon Brown as ever, original page here: http://sheldonbrown.com/tooltips/bbcups.html

**Fixed Cup Tools **

[INDENT]Very elaborate, expensive, and special tools are sold to bicycle shops for fixed-cup removal and installation, but they are not really necessary. A few cheap home remedies can do the job quite well. The first home remedy demands that you have a high-quality bench vise.Simply grab the fixed cup wrench flats in the vise jaws, making sure that you have good contact with all of the wrench flats' meager width. Grasp the bike frame and unscrew it from the cup. This technique works quite well.

If you don't have a bench vise, or if the vise technique happens to not work well on your bike, you can make a universal fixed cup tool for less than a dollar (assuming you have access to a couple of large wrenches).

The tool is an imitation of a $40 shop tool that fits into the fixed cup as a crank spindle would, and pinches the cup. You apply unscrewing force to the tool, and it transfers this force to the cup with this tight friction fit.

The tool consists of a large bolt, a nu tor two, and a few washers. The size of the bolt is not particularly critical, as long as the bolt is strong enough not to break, but small enough to fit through the hole in the cup. I used to use an ordinary 1/2-inch, 13 tpi hex bolt (also called a "capscrew"), which served me well for quitea while. It finally met its match on afriend's Schwinn that had an unusually tight fixed cup; the bolt snapped in two before I could remove the cup.

Now I use a 5/8-inch 18 tpi hex bolt 1 1/2inches long, with a nut, a flat washer, and four lockwashers. The 5/8-inch size is the largest standard size that will fit through the hole in the cup. This bolt and nut both take a 5/16-inch wrench. With my 1/2 inch drive Craftsman six-point socket set, the 15/16-inch socket is also the largest size that will fit into a normal bottom bracket shell.

If you have some other brand of socket, check the fit before you buy the bolt and nut-you might need the next size down (9/16-inch).

[/INDENT]

Home-made tool shown in cutaway bottom bracket cup.

To remove a right threaded fixed cup (French or Italian), tighten the bolt with the socket wrench from the inside of the bottom bracket, holding the nut with the box wrench. Once the bolt is as tight as can be, keep on tightening it, until the cup screws itself out. Once the cup starts to move, turn both wrenches together.

To remove a left threaded (British or Swiss) fixed cup, hold the bolt with the socket wrench and turn the nut with the box wrench.

Use the same tool the opposite way to install the new fixed cup.

You might worry about damaging the cup, but this is not likely to happen. The washer doesn't usually come into contact with the bearing surface. Even if it did, bearing cups are made of extraordinarily hard, heat-treated steel, much stronger than that used to make washers.

[/INDENT]