-

• #1277

In the 1980s I didn’t use a torque wrench

In the 1990s I didn’t use a torque wrench

In the 2000s I didn’t use a toque wrench

In the 2010s I didn’t use a torque wrench

In the 2020s I didn’t use a torque wrenchI need a torque wrench

-

• #1278

No, standards compliance is still based on passing physical tests.

I'm just wondering, if a planetx stem that says x'NM on it, that's been independently tested in physical conditions? .... I would have thought it's just a standard chart, determined by thread/material as you also say.

-

• #1279

The fastener isn't tested in isolation, the bar (a dummy bar if you're doing a stem rather than a complete bike) and stem are tested as a system with all the fasteners tightened to the manufacturer's specification.

-

• #1280

Best tell that to all the airbus engineers 😂

-

• #1281

So the only option for correctly torquing my bolts is to spend years as a bike mechanic?

ఠ ͟ಠ

Um, yeah sure, why not. Fucken precisely what I was trying to say, of course

-

• #1282

Or just ignore me entirely, because your stem faceplate is like a cylinder head in every way.

-

• #1283

Yeah, I thought that would be the case when it came to physical testing... ..Id just be surprised if they actually still did physical testing each time a new stem is produced. Id assumed it was all simulation and charts. So much safety critical parts are purely simulated in CAD now, never tested in real life, surely a boring stem will be too.

-

• #1284

I've got a digital Topeak torque wrench up for sale if anyone fancies it? I don't need it any more, just gonna use my hand and brain to guess at torquing down all the bolts on my bike.

-

• #1285

Brilliant, my work here is done

-

• #1286

IS TORQUE ACCURATE IN CREATING BOLT TENSION?

To appropriately answer this question, it helps to first consider that only approximately 10-15% of the input torque actually stretches the bolt; the remaining 85-90% of input torque is primarily used to overcome friction between the mating threads and friction under the bolt head or nut. Friction is dependent on a number of variables, including but not limited to lubricant type and condition, surface roughness, plating, and material, so it can vary significantly, even among bolts in the same assembly. Additionally, because friction dominates the torque-tension relationship, even a slight variation in friction can lead to significant variation in bolt tension.

It is not surprising then that torque, the most common method for creating tension in a bolt, is also the least accurate method—the general consensus is that variation in bolt tension due to torque control is ±25% to ±35%. A variation as high as ±35% means that at exactly the same measured torque, the tension in the one bolt could be less than 50% of the tension in another bolt. After factoring in any tolerance in the acceptable range of torque values, variation can be even higher. Therefore, accurately torqued bolted joints are not equivalent to accurately tensioned bolted joints.

https://www.valvemagazine.com/articles/back-to-basics-the-nuts-and-bolts-of-torque-and-tension

TL;DR: unless you pay close attention to the difference in how tension and friction feels through the wrench for a long time and use your experience to try to correct for the inevitable variation in friction, your fancy torque wrench may as well be a cargo cult runway marker.

-

• #1287

I would imagine that, for bikes at least people like PX probably design to a tolerance well past the recommended spec and call it a day.

I imagine the closer you get to your specified window being the full window (i.e. 5nm will cause it to fail), the more important real world testing becomes.

-

• #1288

I’m going to join in as well.

To use a torque wrench or not? That is the question.

Collectively we have come to the conclusion that not all wrenches read the same, so why use one? It’s all about consistency. The actual torque isn’t really that important (there is a range of torque spec on most parts) as long as all the bolts are pulled down evenly and to the same torque. This spreads the clamping force across the whole of the bolt pattern, stopping pinch points and therefore more force on one point, which can deform more easily. An even gap on a stem faceplate for example is much better than having one on the piss. Both can be torqued to spec, but only one has the correct clamping force.

So do you need to use a torque wrench then?

On steel parts on a bike probably not, aluminium bits yeah, carbon definitely. As long as you use the same tool on each bolt of an assembly the torque on each bolt will be the same and should be within range. You can do that by feel? You can tighten things so they are tight enough to hold the part and not snap the bolt or strip the thread. But the clamping force will be on one bolt more than the others, this is impossible to avoid. If you are gauging your muscle memory and the “I don’t snap bolts” as your metric then crack on.

The answer?

Do what you like, it’s your bike, you are riding it. OhAll the above assumes that the bolts are free spinning and you are not over coming any issues there.

-

• #1289

The actual torque isn’t really that important (there is a range of torque spec on most parts) as long as all the bolts are pulled down evenly and to the same torque

Do all my stem bolts up evenly to 150Nm by feel, got it.

-

• #1290

150Nm? Are you even trying? Put some hoof on it.

-

• #1291

I just use a 110Nm impact driver for everything

-

• #1292

You jest but I've seen guys use an impact driver to replace nuts 'by feel'.

There's a slight assumption here that everyone who uses a torque wrench has their brain disengaged which wasn't how I remember using one daily, albeit only on scooter engines. I think they're invaluable for the first couple of years or ten engine rebuilds etc until you get a good feel for what a certain application required but I'd often still run it over a cylinder head to double check nothing was under torqued. Which is a bit daft in hindsight as their primary function is probably to prevent over tightening.

edit: Just to add that I would nearly always tighten using a spanner or wrench to where I thought was a bit under and then nip up using the torque wrench.

-

• #1293

-

• #1294

Strong agree. If you've gone to the effort of buying a torque wrench and getting it out for a job 99.9% of the time you're approaching the job mindfully.

I tighten in a similar fashion, but usually torque twice - first below, then in the correct range, then go back over them once more. Where possible/applicable use a star pattern order to tightening. Like Chaley I feel equal tension is important.

Given the previous owner of my motorcycle didn't own a torque wrench or copper slip I'm very much in favour of people using them.

-

• #1295

GMT+10 over here.

At any rate, I think I'm probably done defending myself against piss-ant mockery from those who can't resist a cheap dogpile...

If anyone wants to employ some intellectual substance, I'm happy to engage in an actual discussion though

-

• #1296

TL;DR: unless you pay close attention to the difference in how tension and friction feels through the wrench for a long time and use your experience to try to correct for the inevitable variation in friction, your fancy torque wrench may as well be a cargo cult runway marker.

What an utter bunch of bollocks.

Stating that torque is an intrinsically inaccurate proxy for tension (due to the assumptions about friction that naturally have to be made) is just stating a well know, obvious fact.

Stating that torque as measured when "felt" and when the "roughness of the friction" is "paid close attention to" by "an experienced hand" "with decades of experience" whilst torqueing up a fastener by hand is somehow a more accurate proxy for tension than torque measured by using a calibrated torque wrench is just wild delusion.

If what you are saying is just that an experienced mechanic who manually does up dozens of fasteners a day, is able to more accurately measure torque than a cheap torque wrench of dubious origins and calibration, than that makes sense to me and seems like a reasonable opinion.

-

• #1297

What I'm confused about is that when you torque a bolt up, aren't you only engaging the last relevant ¼ - 2 threads?

At that point how do you ascertain friction vs torque?

Is it by feeling the friction involved in tightening up to that point?

-

• #1298

I'm happy to engage in an actual discussion though

Doesn’t seem like it. This isn’t the first time I’ve seen you spew a complete load of shite then throwing a tantrum when people point out that your opinion is different from fact.

But you’re a qualified bike mechanic so I’ll bow out. -

• #1299

If it helps, my wrists are also pretty well calibrated from years of qualified mechanicing, I quite enjoy getting most bolts bang on without a torque wrench and testing myself by trying to get them within 1/4 turn under torque and getting that click within a 1/4-1/8th of a turn every now and then, or on anything a bit fancy. I also get newbs to play that game as it's good to get a good geek for things. The torque wrench is right though, and the thing I'm checking myself against. I can feel if something feels off and know not to rely on a torque wrench alone if something feels like the threads are fucked or dirty, but I'm still going back to it to be sure if something's behaving weirdly, especially so.

-

• #1300

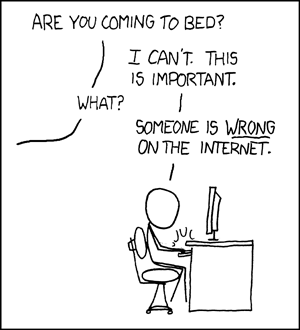

Intellectual substance? What, like this:

Pull your head in. Noobs break shit with torque wrenches. I'm a qualified bike mechanic with decades of experience and I don't break shit.

Honestly, it was an interesting discussion until you went down the Ronnie Pickering route. People were engaging in it in good faith up until this ^ hissy fit.

Fishfabs

Fishfabs gbj_tester

gbj_tester Grumpy_Git

Grumpy_Git Kimmo

Kimmo branwen

branwen Chaley

Chaley TooTallTim

TooTallTim dbr

dbr inchpincher

inchpincher andyp

andyp hugo7

hugo7 dinosaurpt

dinosaurpt snottyotter

snottyotter @freddo

@freddo

tl;dr

Buy a torque wrench, and learn how to use it.