-

• #4777

The rear standlight function is entirely contained within the rear light. If it isn't staying on, the light needs replacing.

(or cracking open and soldering the capacitor back on to the circuit board, as is endemic with B&M lights)

-

• #4778

If I'm remembering correctly, the E3 Triple hasn't been available for at least a year now. We had to switch to the road one E3 Pro 2 on a customers bike at my old work last year. It's possibly quietly discontinued

-

• #4779

I bought both of mine during TCRs and the last one of those I rode was 2019.

I might get another klite for my MTB but for the road/gravel bikes I was just gonna get another E3 Triple. Now I'm not sure. I'll probably just ignore the problem and use battery lights.

Anyone looking to shift a dynamo light? Need something for the Ogre I bought. E3 Triple please? :) Or anything else with too much power.

-

• #4780

I have a triple actually. Shall text you

-

• #4781

Anyone have trouble with the Edelux II rear light connection dropping out? I find it bad to keep the shoe connector in the hole on the front light. Back light stopped working now because I think I've worn down the heat wrap too much and it's shorting by touching the metal of the light. The cable just drops out the hole though. Quite annoying. So every time I plug it back it gradually pushed down the heat sleeve/wrap to expose the metal.

-

• #4782

New heatwrap, and press the shoe connector a bit so it's tighter?

The little plugs can be annoying. Either they don't go on, or slip off. I have broken off more than one. -

• #4783

Mine has been fine.

Are you saying you intentionally remove the wire? Spade connecters are not really made for repeated reconnections.

I would make sure you have a "thin" amount if insulation as this can act as a spring to force the connector loose over time if it is compressed in the available Space.If necessary also gently compress the connector before use to increase the clamping pressure of the female spade.

-

• #4784

I have my rear light wired up with the thin double wire you get with B&M lamps but it keeps cutting out, I lock the bike up so wondering if it’s damaged somewhere, would the thicker son coaxial work better? Might also have to change the cable routing

-

• #4785

Anyone have a spare B&M Secuzed in good shape I could buy off you? The UK prices are MENTAL compared to EU shops which of course do not send to the UK.

-

• #4786

Yeah I got some today from a baumarkt. Will give it a go

-

• #4787

It often cuts out/comes loose so I push it back it. I think it's like you say, the heat wrap bunches up over time. I will try and compress the connector like you suggest. I was also thinking of a tiny drop of super glue. Probably a bad idea though.

-

• #4788

Don't superglue. It will clog things up and if the glue gets into the electrical connection it can act as an insulator

-

• #4789

Don't compress too much...

-

• #4790

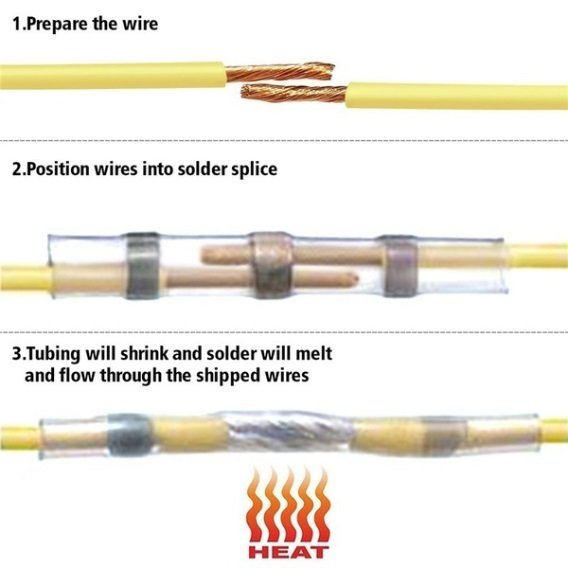

Bike light cable was broken, and bike shop sold me that:

Maybe is is known, but I didn't know it and it is amazing, cable repaired in 2 min.

-

• #4791

mmh surprised this works! regular heat shrink would burn before it melts solder....

-

• #4792

They're special solder sleeves if not clear!

https://www.expresselectrical.co.uk/Catalogue/Terminate-Connect/Heat-Shrink-Solder-Sleeves

-

• #4793

I just twist them together and put some electrical tape over - is this significantly better?

-

• #4794

Electrical tape turns to a brittle, sticky horrible mess after a few months

-

• #4795

Depends on your use case - I connected my rear light with spade connectors because it's on my mudguard and wanted to be able to remove it easily.

If your setup is permanent then and you want it to be waterproof/welded together then the sleeves are a great shout.

-

• #4796

Cheers Che and @Grumpy_Git with a little compression and some new heatwrap it worked well and feels more secure.

On another note any good advice for top tube wiring solutions on frames with top tubes like a cross check? I've got it taped underneath the tt but it seems like there must be a neater way?

Would it be dumb/even work to wrap the rear light cable in a spiral around the exposed section of rear brake cable between the braze ons? Would probably cause too much friction I guess.

1 Attachment

-

• #4797

Just thinking out loud: if you got some cable liner and ran the brake cable through a liner on the exposed bit, you could heat shrink the wire to the brake cable without friction being an issue

-

• #4798

Seems like it would work. Maybe would need one or two bits of tape or glue to hold the liner to the top tube? Maybe not even if I used that really thin cable liner.

-

• #4799

No because the brake cable is under tension and is raised off the tube by the stops so just cutting a bit of liner the exact length between cable stops for the inner cable to run through would be fine. The dynamo wire would also then not be attached to the tube itself, only running down the brake cable so I'm not sure if you'd consider it neater than taped to the underside of the tube but it would still be pretty neat.

-

• #4800

Just found this picture online of a wire with heat shrink to the brake outer and then taped to the tube underneath the exposed brake cable. That's an alternative

1 Attachment

grams

grams PhilDAS

PhilDAS hippy

hippy Thrasher

Thrasher sorethroat

sorethroat c.h.e.

c.h.e. Grumpy_Git

Grumpy_Git packet

packet Jameo

Jameo Julien1A

Julien1A RabiCycle

RabiCycle se1derful

se1derful lemonade

lemonade

@hugo7

@hugo7

They're offering discounts to TCR riders so I was going to order direct after convincing a TCR rider to act as an intermediary. I figure, I've done 4, I could've claimed the discount on all four. Just now they don't do my favourite light I'm not sure what I'll do. I could get k-lite for the off-road stuff but $$