-

• #152

I remember going to an IoT/industry 4.0 conference a few years back where Trek had an MTB that was loaded with 4G enabled strain gauges. The idea is that you go out and shred and then synchronise the camera data with the strain gauges so you can see how the different moves affect the frame loading - this can then go into the loading model to give empirical data (for a specific geometry)

More info here https://ifwe.3ds.com/sites/default/files/2017-12/cgr-brochure-simulia-trek-bicycles.pdf

1 Attachment

-

• #153

Agreed. I have a model of a bridge created using Additive Flow FormFlow (Topology Optimisation). It can carry an impressive weight, but it's pretty tricky to remove it from the build plate without trashing it due to the incredibly thin walls.

1 Attachment

-

• #154

In recent 3D-printed bike news. Sunweb Team are going to have DSM as main sponsors for next year which reminded me of these arm-rests printed by DSM for Sunweb in this years tour.

info here: https://www.dsm.com/content/dam/dsm/additive-manufacturing/en_US/documents/dsm_template_team-sunweb.pdf

It does not look like these are rider specific items, as far as I can see they used AM because of the range of technical polymers available, the ability to create multiple iterations quickly for testing and the fact that designs can be quickly and easily modified to suit different bars.Whether having DSM as main team sponsor will result in more pro-peleton AM remains to be seen.. Last I saw DSM had sold off their AM business

1 Attachment

-

• #155

Printed armrests available here for a mere €175 https://teamsunweb.shop/product-category/gear/

(but if you want something slightly different for much less, PM me) -

• #156

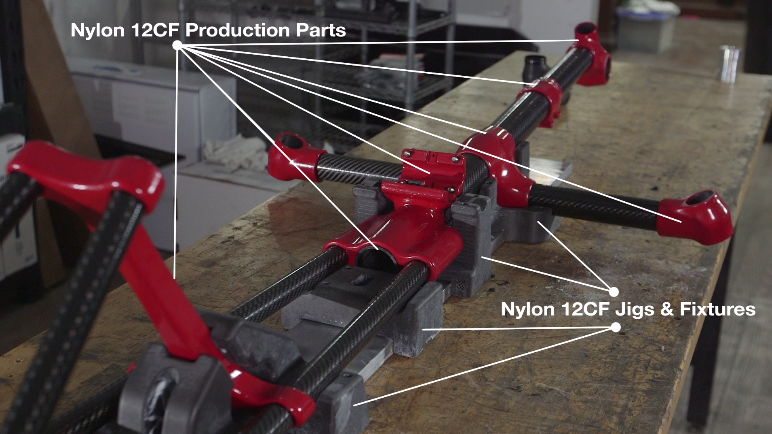

Lugs for a 'bent FDM printed with Stratasys Nylon 12 CF filament

https://www.tritech3d.co.uk/fdm-nylon-12cf-the-best-alternative-to-metal/

Whitepaper here: http://prototypingsolutions.com/wp-content/uploads/Case-Study-FDM-Utah-Trikes-A-Game-Changing-Material-EN.pdf

This is a chopped fibre filament that requires a print head mod so it's only for Stratasys FDM

printers.For non-stratasys printers there are other such filaments available e.g. - https://shop.3dfilaprint.com/carbonx-gen-3-carbon-fibre-500gms-black-nylon-175mm-3d-printer-filament-22071-p.asp

You'll be wanting a hardened steel nozzle but apart from that they're pretty straightforward -

• #157

https://www.magura.com/en/components/news/2019/hc-loic-bruni-3d-printing/

Loic Bruni x Magura - superlight 1-finger lever printed on an SLM Solutions

Weighs 16g - I'm guessing it's their AlSi10Mg powder that's used for this

Although they talk about customising the ergonomics there's just one geometry for the printed lever so it's not mass customisation just production AM (€77.89 /piece)

I guess it's only being printed because the demand for such an upgrade is limited so it's not worth tooling up for die cast and the geometry is too complex for cost-effective machining -

• #158

Staying with the subject of printed bits for hydraulic discs, this sort of thing is on my longer term projects horizon.... (although I'd hope to make mine more ergonomic/tidy)

The designer is selling through the Shapeways portalMaterial/process on this is the relatively cost-effective binder jetting method where the stainless powder is inkjet printed with a bonding agent. In a subsequent curing process the binder is replaced with bronze to create a reasonably strong (10% porosity) material rather like a sand casting.

-

• #159

https://www.stratasys.com/explore/case-study/santa-cruz-bicycles

Santa Cruz using FDM to print (non-functional) prototype frames and printed mandrels in their 'production' lay-up tool. Not particularly brave/exciting but progress of sorts

-

• #160

Can I just say, that although I have nothing to contribute to this thread, I do find it fascinating and I appreciate your work @Rik_Van_Looy

-

• #161

Likewise; I just came across this thread and have read my way through it. I don't think we covered AM at all during my aero eng degree, though I guess some of the lecturers may have been doing research on it.

Is fatigue resistance not an issue with printed lugs, or are there AM techniques where this isn't a problem?

-

• #162

3D printed bike parts in the news today - turns out Alex Porter handlebars were made by Bastion https://www.instagram.com/p/CSGNtbhhmbn/?utm_medium=copy_link

1 Attachment

-

• #163

I guess like most industrial processes, 3d printing metal needs to be done just right if it's going to be strong. Plenty of evidence out there that 3d printed ti can and should be strong...so what went wrong?

-

• #164

Fairly obvious use of 3D printing in creating bespoke components to improve accessibilty and comfort. However I like that we've reached the point where people are able to produce the parts themselves.

Although the 3D scanning might be out of reach for most people, it looks like phones are quickly becoming more than capable enough to perform the scanning operation.

http://hearables3d.com/demo/smartphonescanning/ example of ear scanning app for custom earphone tips

-

• #165

🤷♂️

1 Attachment

Rik_Van_Looy

Rik_Van_Looy

Scilly.Suffolk

Scilly.Suffolk Thrustvector

Thrustvector

Stonehedge

Stonehedge Pensprite

Pensprite Tijmen

Tijmen

In my (admittedly very limited) experience of playing around with topology optimization using a Markforged 3D printer, I've found that a sensible set of loading cases combined with not optimising too aggressively goes a long way. It's not hard to see how something like those lugs with tiny little 2-3 mm tendrils wouldn't be very impact tolerant...