-

• #4852

I thought the point of NW was so the chainring didn't throw the chain so easily.

What's the point of having it on jockey wheels which are surrounded by a cage?

-

• #4853

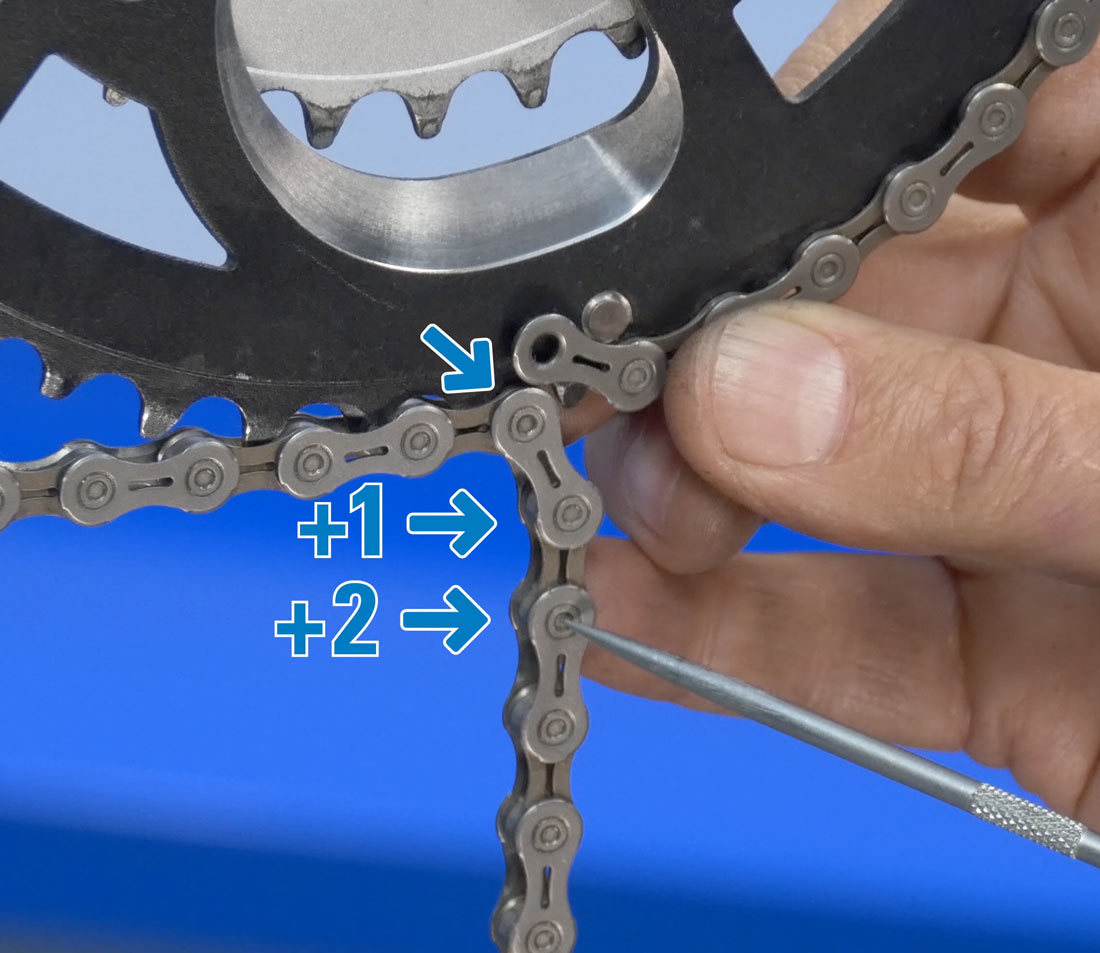

I've always sized big-big without derailler and then added a link (two rivets) as in Park Tools easy method

https://www.parktool.com/blog/repair-help/chain-length-sizing

(don't forget the quick link counts)

-

• #4854

NW pulleys on my SRAM RD are just annoying. It's possible to make the upper pulley skip a teeth, then it won't engage properly and you have to put with the noise until it jumps back to the right place or do it by hand and get greasy fingers

-

• #4855

I thought the point of NW was so the chainring didn't throw the chain so easily.

What's the point of having it on jockey wheels which are surrounded by a cage?

I don't know. The Shimano pulleys don't have narrow/wide profiling, that I can see:

And the SRAM 12/14T pulleys from Kogel (which matches what the mech ships with) have a narrow/wide profile on the lower pulley, so I'm assuming that the reason they specified the 14/14T set was that they didn't have it.

But @TotalShanner had no issues with his Shimano HG+ chain on the lower pulley wheel, so who knows?

-

• #4856

I may try hope pulleys just because of that

-

• #4857

Yeah, it just seems like a mistake to me. I've still not used my TT NW ring on anything but turbo and aero testing so I've not been going faster enough to need the gears where I'd usually throw a chain. Maybe I'll just stop pedaling every time I hit 30mph like some kind of e-bike shutoff, just in case.

-

• #4858

Well you've opened and fitted the pulleys so does that mean you can't send them back now anyway?

Give it a try with the sram pulleys first. I'd be interested to see if you get on OK. I can send you a video of what mine look like while pedaling if you want. Really no issues.

The comments in that article are the only ones I've really seen saying they had issues with the pulleys. But there's not really a great deal of info out there on what is obviously a niche set up.

-

• #4859

What's the point of having it on jockey wheels which are surrounded by a cage?

Its a good question. I dont think there's any logical answer.

Up until 12 speed eagle sram used NW teeth on both jockey wheels.

But the top jockey wheel would sometimes go out of sync with the chain making it feel rough. Changing gears down then back up the cassette would fix it.But now on 12 speed eagle the top jockey wheel doesn't have the NW profile but the bottom one does.

But why? I've yet to find a good answer. -

• #4860

this has always been my go-to too. will have to check the shimano spec and see where i get to

-

• #4861

This has made me think about what could potentially be causing the problems for the folk commenting in that article.

I have no issues with the chain meshing with the lower NW jockey.

But it might be possible that those with issues inadvertently done something wrong when feeding the chain through the derailleur.

The chain might have been feed through the NW jockey and ending up sitting on the wrong tooth and being out of sync. The same way folk had the issue on the top jockey wheel on 11 speed.

The fix for them might be as simple as braking the chain and moving it up and over one tooth on the cassette and jockey wheels. Thus putting it into sync.

Does that make sense? -

• #4862

It does, it's rather worrying (with regards to their mechanical ability) if that's the case though.

I'm going to keep the Kogel wheels in there - after all, what's more fun than setting up AXS mechs of an XTR drivetrain? Setting up modified AXS on an XTR drivetrain.

-

• #4863

what's more fun than setting up AXS mechs of an XTR drivetrain? Setting up modified AXS on an XTR drivetrain.

Riding the bike? :)

-

• #4864

Riding the bike?

Don't be silly!

-

• #4865

You show me proper off road trails I can get to and ride in my lunch hour from SE23 and I’m all ears.

-

• #4866

Setting up modified AXS

As an experiment I took the cage off and tried to put on a shorter cage from a 7 speed gx dh mech.

I wanted to see if I could have 7 speed axs on my dh bike like this prototypeBut the cage I had didn't fit correctly, the pin hole for the return spring was in the wrong place. I realised the prototype one uses a Force 1 short cage.

But I abandoned it as I had to set the limit screws to physically stop the mech shifting beyond the biggest cog. I was worried that the motor could be damaged and didn't want an £800 paper weight.A complete waste of two hours but fun nonetheless.

-

• #4867

only option

-

• #4868

Not showy enough

-

• #4869

Watts saved by large jockey blingness < watts lost by absolutely filthy drivetrain

-

• #4870

What's wrong with getting sick air bro off the curbs and shit like every other dirtbag?

-

• #4871

All show, no go.

-

• #4872

.

2 Attachments

-

• #4873

.

2 Attachments

-

• #4874

Works ok in the stand.

-

• #4875

What has this got to do with Di2 and electronic groupsets?

hippy

hippy Dammit

Dammit swedeee

swedeee PhilDAS

PhilDAS amey

amey TooTallTim

TooTallTim

andyp

andyp

Kogel does not have narrow/wide teeth on either pulley.