-

• #127

similar process to the instructable on previous page but with carbon frame tubes

https://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=148513

-

• #128

Remind me why IS-mount calipers have disappeared again?

-

• #129

The main structural reasons for PM over IS is that the materials of bolt and mount are better suited to absorbing the braking loads into the fork or frame than with IS. The bolts themselves are loaded in tension which is where they're strongest but on IS mounts they have to deal with a shearing load which is where they're actually the weakest. PMs also require less material to be used in the frame/fork construction and so you end up with marginally less weight. I believe when Fox went from IS to PM in 2008 they claimed something like an ounce of weight reduction in the lowers.

https://www.pinkbike.com/forum/listcomments/?threadid=127672

-

• #130

That's all well and good, but surely if you're using a PM caliper with an IS adapter you're negating both the advantages listed?

-

• #131

Yes, but it would have solved the problem of the stays being nowhere near the mounting points of a PM caliper. But instead of that Phil came up with a more practical solution, cutting up a PM braze-on:

About the same effect as the 3D printed solution I posted but a lot less involved for me, lots of filing for Phil though. This and more fun in my current projects thread.

-

• #132

Much better!

I've always been turned off by the optical clusterfuck of IS>PM adapters, bolts, concave/vex washers etc. The above looks very elegant given the constraints of a boost frame.

-

• #133

Spencer Wright (Founder of the rather excellent weekly newsletter 'The Prepared') did a couple of interesting reports on a Ti-printed mast topper

http://pencerw.com/feed/2015/3/15/3d-printing-titanium-and-the-bin-of-broken-dreams

http://pencerw.com/feed/2015/8/6/3d-printing-titanium-learning-to-learn-from-success

-

• #134

The same guy used nTopology to create a top cap weighing 4g

http://pencerw.com/ti-top-cap/batch-one-ti-top-caps

More info here https://www.bikeradar.com/features/the-140-3d-printed-titanium-top-cap-that-i-cant-help-but-love/ -

• #135

There was also talk of a stem too

https://pencerw.com/feed?tag=stem -

• #136

Continuing the theme of superlight Ti widgets here's a printed chain catcher (weight: 10g) from Garmin mount specialists and general AM-evangelists Raceware direct

Available from their online shop for a princely £30 -

• #137

Interesting possibilities for those with home printing:

https://scitechdaily.com/move-over-plastic-desktop-3d-printing-in-metal-and-ceramics/

-

• #138

If you get EAA (Experimental Aviation Association) membership at $40 a year you can get a student copy of solidworks premium for free. Obviously its non commercial but it's helped me a lot in fixing various bits and bobs round the house with my printer.

-

• #139

Yes, worth keeping an eye on to see if the filaments become a bit more affordable.

The BASF version's still pretty pricey - https://3dgbire.com/collections/filaments/products/ultrafuse-316l-metal-filament-2-85mm-3kg?variant=32277325348917

I don't know how the thermal process works to sinter that Tiwari product but for the BASF version you have to ship the 'green' part to one of their partners for curing.

-

• #140

this is good to know.

Are there any restrictions to a student version of premium?

Does it still watermark your 2D drawings? -

• #141

wow thats awesome i did not know that. Thanks! will check it out

-

• #142

Yeah unfortunately it still watermarks drawings and has a pop up when opening part files. But you do get access to the simulation and CAM packages.

-

• #143

yes they don't like cheap/free licenses ending up in commercial use...good to get the simulation tho - is the FEA for single parts or assemblies?

-

• #144

Recent article on Sturdy - https://www.3dprintingmedia.network/sturdy-cycles-works-with-ram3d-on-production-of-custom-titanium-bicycles/

fully printed headtube - they've even gone to the trouble of polishing them

more pics here: https://www.ram3d.co.nz/sports-performance (print bureau) -

• #145

printed forks tho

-

• #146

Those hourglass thingies look like material testing samples? If so he’s really taking things seriously.

-

• #147

well spotted, yes and they can record young's mod or fatigue strength or whatever specific to each lug set

-

• #148

At the Advanced Engineering show at the NEC last year, I think it was

Renishaw had 3D printed polished Ti bars on displayWas this the sprint version?

or was it the hope/renishaw project where it goes straight onto the fork crown

-

• #149

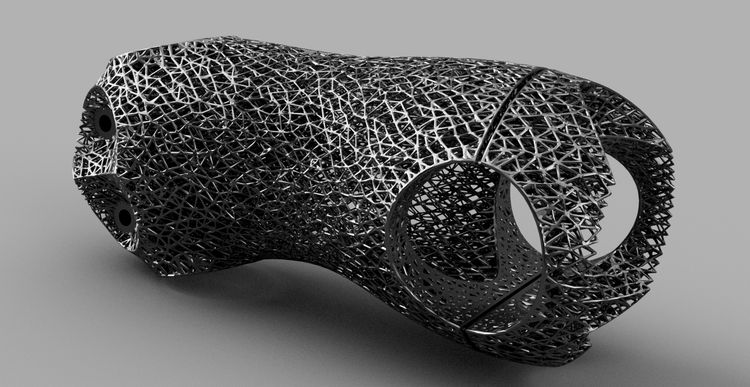

I've seen this in the past and I think it's stunning. I'd love to see some in depth evaluation of stiffness, weight, durability etc vs conventional lugwork.

-

• #150

Yes, me too.

As with all optimised geometry, form is driven by loading case.

With all the development of optimised carbon fibre frames presumably there's data describing flex during sprinting, deflection on crank strike or what happens when the bike falls over etc, but you could imagine scenario in which something so heavily optimised and directional in strength could fail in an unforseen loading scenario...

Rik_Van_Looy

Rik_Van_Looy ectoplasmosis

ectoplasmosis Tijmen

Tijmen matteroftaste

matteroftaste Pensprite

Pensprite Biggles567

Biggles567 Slappingpythagoras

Slappingpythagoras

I assume you're referring to Adrian "carbon wasp" Smith

https://youtu.be/5gFyqFGtqsM

I think he's upped his game a bit since those days tho

last interview i read he was talking about printed moulds and custom silicone bladders