-

• #102

Maybe offer a reduced price on the first dozen frames or so including terms of sale, make them for friends and family, cut no corners on the production and see what happens?

-

• #103

I wouldn’t paint it, keep it raw, oil/wax/lacquer etc and just let it do it’s thing overtime. Or do it on stainless

-

• #104

That was the one!

-

• #105

Insurance is no fun, especially as you'll need to speak to people directly to get quotes, but just get it. The last thing you need is someone suing you in the bad luck instance that a frame fails. There's no such thing as friends and family if you cripple someone and the blame/claim culture gets to them. Worth remembering that unless you're a registered business, any court action will be taken against you personally, so its not worth risking your home etc!

One of the first things we did was to take out public liability insurance. It's a huge chunk every year, but any framebuilder worth their shit has it because anything can happen. A bad batch of tubing etc...so it's not just covering your handiwork. Some customers will also want to know that you have insurance, it's just one of those things that separates a hobby from a business.

Admin is a chore. Insurance is pretty much the worst of it. That's why my other half has me do it all, so he can be in the workshop building, not arguing with insurance people on the phone about the difference between welding and brazing etc!

-

• #106

Nah my liability insurance is 420 a year based on 2000 units sold and 950 to insure the workshop for theft fire and loss of earnings , the insurance for doing military stuff that goes to the bottom of the sea however

-

• #107

2000 units sold

As in 2000 frames, per year? Or ever?

I don’t imagine I’ll be doing many more than a dozen or so a year for the first few years.

Would you or @RunRabbitRun be willing to share the name of your insurer? By pm if you prefer. Like I say, not a clue where to start!

-

• #108

Actually wasn’t as hard as I’d imagined finding a starting point.

Phoned Simply Business who couldn’t help but have given me Biba’s number. I’m on hold with them just now.

-

• #109

We go through a local broker. We've been with them from the start, so we've negotiated a discount and less fees etc. They always work out far cheaper than anything through Simply Business/Biba etc.

-

• #110

Hiscox are the underwriter on the manufacturing part Loyds underwrite the manufacturing equipment and my consultancy work, for a startup you will probably need a good broker, when I worked with the AMRC a very good guy in Sheffield ran a company called Coversure he was great with startup / ideas based companies who were new and very thorough in that you couldn't cut corners and helped find out exactly what your company did to find the right policy.

the numbers thing just outlines their exposure to risk 50000 units out there is a higher risk than 5 , however 1 year being in business is a lot less than 23 or so years of never having had a claim it depends what the underwriters conditions are, they vary considerably , some wont touch a startup without hefty premiums , some just don't understand your business , and this arty farty thing falls outside of some people idea of manufacturing so they have no pigeonhole to put it in

to be honest what you get will be very different to what I get , I tried to explain this once upon a time to a kid on the faceache group , it matters very little what im paying or the next guy, your circumstances will unfortunately be different as each is underwritten on its own factors,

I seem to have reverted to being user 93037

Edit one other thing are you working from your shed in the garden? or do you have premises there may be implications on insurance telling the council etc if working at home and there are most likely insurance implications on having oxy fuel at either business or home

-

• #111

Exactly this!

No two insurance policies are the same!

-

• #112

Yeah I know the numbers will be very different, I was just asking about who you guys were insured with as you know, for car insurance you go to compare the market, lve, direct line etc but I had no idea where to even start looking for liability insurance. But I’ve gotten over that hurdle now so it’s all good.

Yeah I’m working out of a garage at my flat. Pretty much a lock up. I’ve asked for just liability insurance, not cover for the workshop (would probably be illegal to have the garage double insured) or tools, stock etc.

Given that I’m using oxy propane rather than acetylene, hopefully I can keep the council out of it.

I’ve elected to not let my home insurance know about it as the way I see it the risk is similar to keeping a gas barbecue in the garage and you wouldn’t have to declare that. From what I’ve read as soon as you mention brazing or welding to insurers they shit themselves because they don’t understand it so you’d get a situation where the same insurer would be fine with the old biddy that lives below me that chain smokes and has a flat full of oxygen cylinders because she has emphysema but would refuse to insure me because I’ve got one cylinder chained to my garage wall.

-

• #113

Got an insurance quote back today and its not too bad. If I were to pay it monthly, selling a stem a month would about cover the cost of the policy.

I'm going to a business gateway thing tomorrow evening and meeting an advisor next tuesday so I'm not going to take anything out yet. Probably want to get at least one other quote to compare it to as well.

-

• #114

...go through a local broker...

Glad I listened to this, got the quote back from a plan and was going to just go for it, called a local broker and they’ve came back with a quote 1/3rd the price for the same (still to read all the documents properly) cover.

-

• #115

wow, thats a big difference, nice one

-

• #116

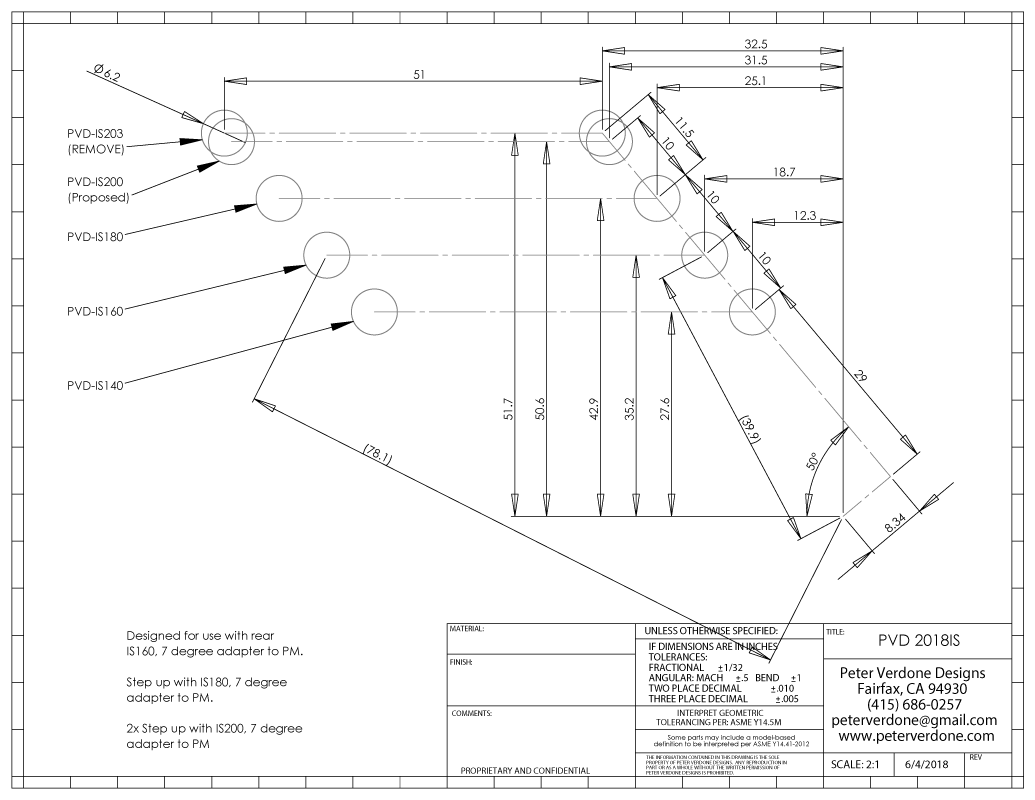

Can anyone point me in the direction of a simple guide to disc brake mount dimensions?

Or explain this Peter Verdone one to me (my brain doesn't really seem to be working when I look at it)?

Edit: NM, a wheel/hub with a rotor attached is going to be the easiest way for me to position the mount I think.

-

• #117

One of the more notable thing about experts is that they are able to elegantly describe complex subjects as systems and systems of systems (Feynman Method). More, they can tell you how systems came to exist and problems with popular understandings. Even better, they can spot flaws in systems.

Take my recent work on disc brake caliper mounting for bicycles.

Goodness, that's quite some opinion he has of himself

-

• #118

Yeah I read something on his website a while ago and all I could think was “you love the smell of your own shite don’t you?”.

I wouldn’t have posted something from his site but it was the only diagram I could find.

-

• #119

haha i got the same feeling, he clearly knows his shit, but yeah...

-

• #120

I'd still like you to have a crack a disk tab on my crusty old frame. Will pay you. Also if you fancy doing a chainstay yoke retro-fit a la Hulsroy / mankkis that'd be amazing, depending on how much money I have. Not massively attached to the frame + promise not to sue if it explodes.

Not sure when I'm over in Glasgow though, earliest would probably be ~21st Sept?

Got to get this stuff done before you become too successful

-

• #121

Cool, I'm up for it!

I'm working all day the 21st but you can come see me at the velodrome if you like.

Job I'm doing just now is a Kona A'ha, widening the rear spacing to 135mm and adding the (slotted) disc tab. Was hoping to put it inside the rear triangle but I think it's going to be too far back and too low due to the looptail design.

-

• #122

Go and read one of the standard sram or Shimano specs and use that, it's available on sram tech docs

-

• #123

I got the frame spread today so just chucked a wheel in it and offered up a caliper and the mount and stuff.

Took a while but got there in the end.

Mount I'm using is one of these,

Can't go inside the rear triangle because the track end and looptail design mean the caliper would be miles away from the axle and too low down so decided to put it ontop of the chainstay but the mount is a pain in the ass to work with because you can just rotate the mount and caliper around to find a good fit, you have to keep the slots in the mount parallel with the track end.

Ended up cutting the mount into two pieces which gave me a bit more flexibility. Will tack it tomorrow and check it's going to work.

-

• #124

GCN put out an intersting video on moots today

https://www.youtube.com/watch?v=Jvqo9Ino1lE

worth a watch, they have it dialled at moots for sure, whether you think ti is pointless or not...

-

• #125

So, oxy propane peeps, what sort of supply pressure settings and flame sizes are you using? Oh and nozzle/tip sizes too?

I've been using the smaller of the tips that came with the Weld-Equip kit, think its a #3, I've been setting my regulators to give me between 1 and 2 bar supply pressure and I've been using a flame that's probably about 10-15mm inner cone with the feathery outer flame around it.

Matt from Rothair Cycles had me over to his workshop yesterday for a wee fillet lesson and he has his (oxy/acet) torch set up so differently.

He was using a higher supply pressure, 4 bar I think, a #1 tip (though he did say he'd sometimes use a larger tip for fillets) and an absolutely tiny flame, like 3mm of inner cone probably. His torch was almost silent whereas mine is roaring when I'm using it.

I did a fillet at Matt's last night and while there was still plenty to be working on, it was the neatest joint I've made yet by quite a margin.

I'm hoping I can get a couple practice miters filed while I'm at work today and can have a bash at brazing them with my torch set up more like his tonight but I'm worried that I'll not be able to replicate what I did last night with my cooler oxy/pro flame.

I also found it interesting last night that Matt purges his pipes at the end of a brazing session but doesn't touch his regulators. I'm sure I'd read that it was good practice to back the ajusters off till there was no resistance felt so I've been doing this after every session. Matt also has a day job at Shand by the way so I presume they must be treating their regulators similarly, makes me think what I'm doing is a bit ott.

Heldring

Heldring Dogtemple

Dogtemple RunRabbitRun

RunRabbitRun mike_mcdermid

mike_mcdermid M_V

M_V user93037

user93037 Biggles567

Biggles567 M_Vatwork

M_Vatwork frankenbike

frankenbike

Oh well :) I'm still gonna pick up some SiB rod some time for the heck of it