-

• #38627

Ha, brilliant.

There's a thread on Pistonheads Aston forum, about who inspected your car, and all the Barry Griffin people have fault-free cars, much to the annoyance of some others.

-

• #38628

Back in the game... Cam belt and other bits done, should touch wood, finish the major service. The coilover fund is looking healthy too but thinking I might wait until the spring before getting them on.

2 Attachments

-

• #38629

Looking good.

Are you going to supercharge it?

-

• #38630

Ok, riddle me this:

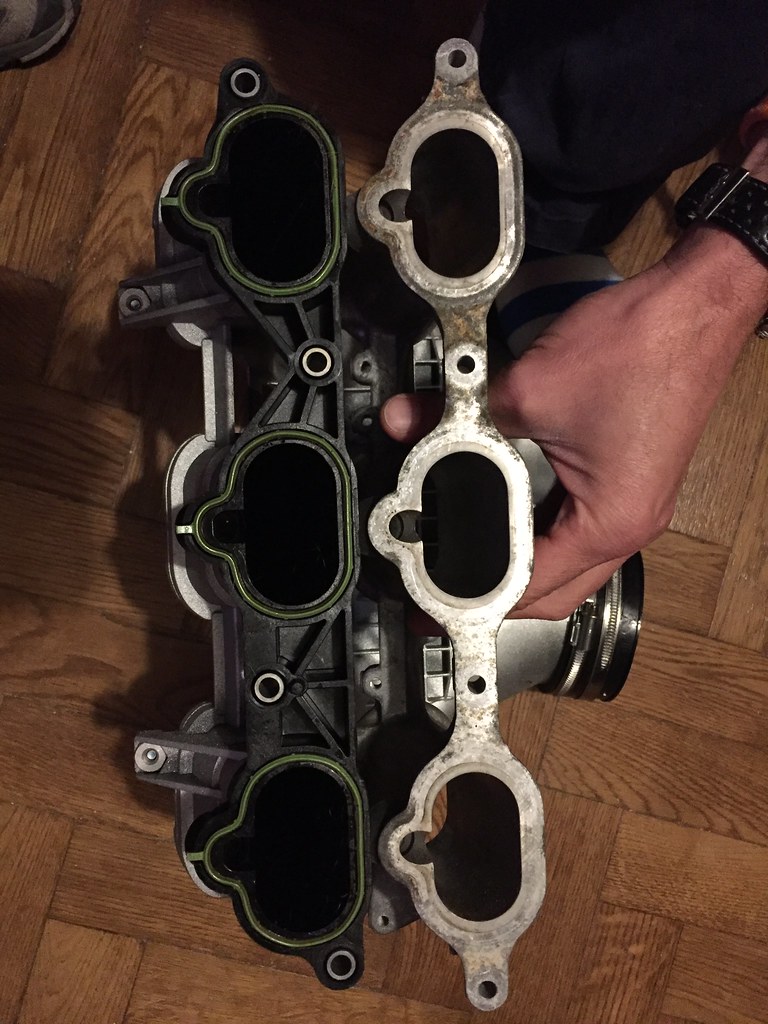

The manifold on the left needs to have the bolt pattern of the one on the right.

It's made from some form of plastic, and in an ideal world the method of adaptation would not (overly) alter the plastic manifold beyond that which is the minimum.

-

• #38631

That's the question! I prefer this idea to turbocharging if it ever did happen, but it wouldn't be for a very long time. My plan was always to tidy the car up and do some handling mods before adding any power.

I'm a secret Honda fanboy and have always wanted to build a tasty but reliable naturally aspirated K/F series engine and recently I've been looking into these swaps into MX-5's. It's all just dreaming at the moment but think I prefer this 'journey' as opposed to the super/turbocharging route.

-

• #38632

A friend of mine produces a really nice super charger kit for MX5s, check out Salon Motorsport on facebook

-

• #38633

Okay thanks will take a look, a supercharger (esp with ITBs) would be awesome.

-

• #38634

I recon you can produce the same flange in 3D printed glass filled nylon. Would be kinda spendy but should work if designed right.

Otherwise copy in aluminium, CNC and weld on

-

• #38635

The whole of the 3.8 litre M97 manifold is plastic - would need to be bonded on.

Hat tip to Danstuff for this suggestion:

Cut away only those parts of the manifold flange that foul the position which the bolts need to be, put a plate over the top of the flange that can take bolts down into the head, compressing the M97 manifold between the plate and the head, holding it in place.

?

-

• #38636

Yeah sensible idea, machine off the tabs and make something that fits over the top as a compression plate.

Could do that with daily basic water jet cut plate and some sleeves.

Bonding to the plastic should be relatively simple depending what the plastic is

-

• #38638

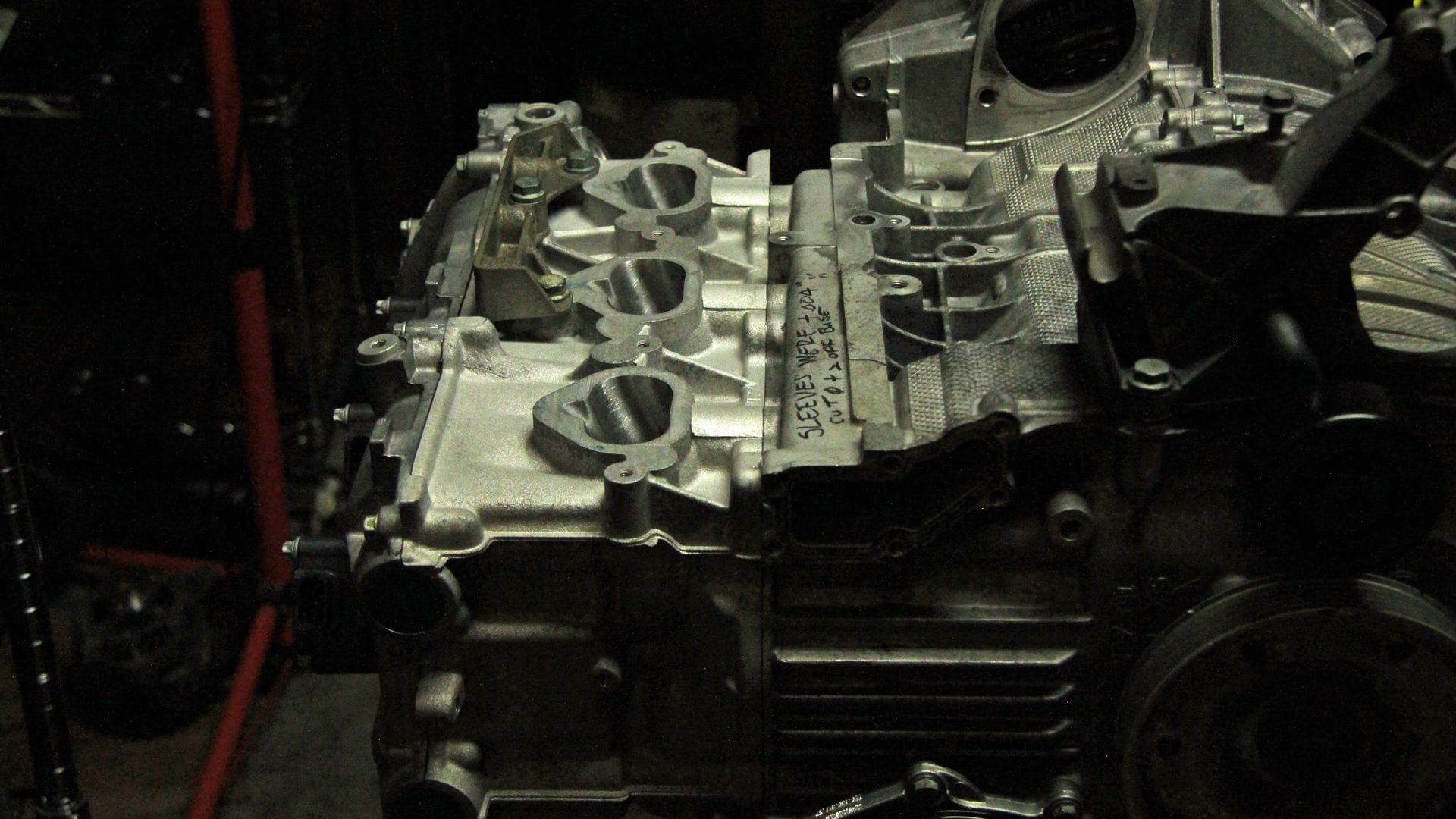

Or, would it be easiest to drill and tap the head?

Looks like there are bosses there to drill.

-

• #38639

I nearly said are you sure the heads aren’t a similar casting you can just drill and tap to suit

-

• #38640

I'm wrong, looking at it more closely - the M97 manifold requires a single bolt between ports which is centrally placed between the ports, but offset from the centre line, and there's no boss on the M96 head in that position.

-

• #38641

Rather than modifying the plastic intake my gut feeling is that it would be easier to build up the head with weld then drill and tap it in the correct places.

-

• #38643

I'd go with danstuff's suggestion; drilling into a stressed component like a head would make me antsy, even though a rational appraisal would suggest it's probably fine.

-

• #38644

What would the implication be of moving the injector up ~15mm in reference to the intake port?

-

• #38645

potentially ok if you also change it's angle at the same time - it needs to point at the back of the valve head rather than the wall of the port (assuming valve is in the cutout into the head) or at a tangential angle to the airflow in the manifold, depending how far up the tract it is

-

• #38646

Hmm, I think that's out then- making an adapter plate would be to avoid modifying the manifold.

If it means that we have to modify the manifold then it's a false economy, bringing with it potential issues with clearance in the engine bay etc.

-

• #38647

Had 5 weeks of a 2017 Hyundai sonata while in the USA and had never realised how much nicer modern cars were to drive in terms of comfort. Did 7 hours to and from LA with only a 15 minute break without much bother.

I'd be dying in the 06 micra i drive in the UK.

-

• #38648

What is the torque for the bolts?

-

• #38649

Dunno, why?

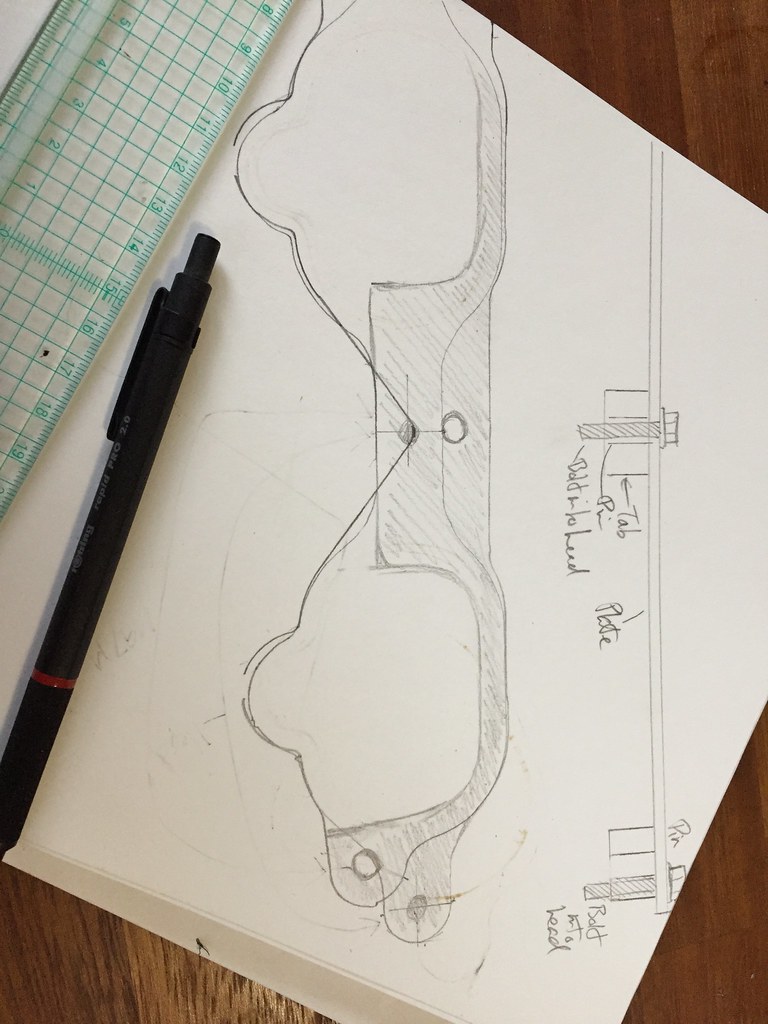

Here's a first pass at Danstuff's idea:

A flat plate with pins that locate into the bolt holes on the manifold and holes (with guiding barrels down to the head preferably) that allow bolts through the plate to meet with the mounting holes in the head, clamping the manifold between the plate and the head when the bolts are tightened down.

-

• #38650

Anything to stop you taking the plate right round the other side to even out the compression?

I doubt it torques down super hard but for the teeny bit of extra weight you may as well.

bq

bq jambon

jambon

hugo7

hugo7 Dammit

Dammit mcmyk

mcmyk Thrustvector

Thrustvector rogan

rogan lynx

lynx Hefty

Hefty

AIUI there are now fake Barry Griffin plates available on the black market, such is his reputation.