-

• #6977

How does anyone maintain a tape measure for 30 years? Isn't the riveted lip attachment all wobbly by now adding a couple of 16/ths to every measurement?

I am amaze. I salute you.

-

• #6978

Re: laser measures, I bought a cheap one after over-borrowing a friends Leica all the time (for woodwork they're great too) and couldn't get accurate, consistent measurements which totally defied the point. So I bought a Leica Disto DXT on offer for just over £100 and it's mm perfect and rock solid. Buy cheap, buy twice (unless you're only using it once!)

-

• #6979

Not noticing details such as coloured numbers puts a level to how often I use a tape measure.

I tend to reach for a steel rule as the measuring stick of choice - retired Technology teacher, more engineering than woodwork. -

• #6980

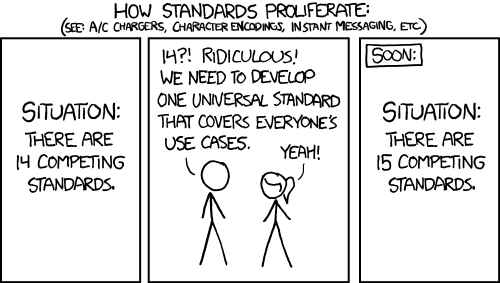

Ahhh technology - that explains your evangelism of a new non-existent standard for small use cases.

(I'm in IT.)

-

• #6981

Ha! Stolen...

-

• #6982

But the need for insulation and wiring does preclude the use of 2x4 stud walls.

How so?

-

• #6983

I'd build the frame out of 2".2", fill the gaps with kingspan/celotex, DPM stapled to the outside then shiplap. Recess the electrics somewhere you won't nail or screw through at a later stage. Clad the inside with ply or T&G panels if posh.

The shed market is so competitive if you look around it isn't that much cheaper to buy a half constructed shell that'll be a piece of piss to erect and probably last 20 years with a decent bitumen roof and the occasional lick of wood treatment.

-

• #6984

How does anyone maintain a tape measure for 30 years? Isn't the riveted lip attachment all wobbly by now adding a couple of 16/ths to every measurement?

It's meant to be wobbly.

The lip moves the same amount as the depth of the flat bit of the lip measures.

When you measure the inside of something (by pushing the lip against the end of the tape measure) it moves in by the appropriate distance and the tape measure gives the right measurement to the outside of the lip.

When you hook the lip over the edge of something the rivet allows it to move the same distance as the depth of the lip and the tape measure gives the right measurement to the inside of the lip.

I doubt wear and tear would make it add more than the expected amount...

-

• #6985

Where's the fun in a tape measure (unless you're a cat, that is).

Lasers for everything!

-

• #6986

It's supposed to do that - so that you can measure from the outside, or the inside, and account for the 1/16 inch thickness of the lip.

[Edit] Dagnamit. Page refresh fail.

-

• #6987

mindblown.gif

-

• #6988

You learn a new thing every day.

Weirdly, for someone hanging out on a bike forum, this is by far and away my favourite thread here. There's no shouting, very little arguing - just helpful people building Good Things. I think this speaks to the better bits of human psyche... much the same as riding and tinkering with a bike does, possibly.

-

• #6990

In North America wall cavity insulation is cut to just under 16" wide so it slots in nicely between the joists. The boxes for power sockets also mounted to the studs, spacing is less important but yeah, if you're building a, powered, insulated shed, might as well use the generally accepted building standards.

-

• #6991

It's not my shed. I'm just contributing to the wall stud chat.

(fnar)

-

• #6992

Ah yes. Understood. I phrased that poorly. What I meant was that the small movement will increase over time and throw the numbers out. I've rarely had a tape measure last more than a few years before those that 16ths starts to into 8ths.

(also @TW)

-

• #6993

Cheers, that's exactly what I came here for!

-

• #6994

96'' divided by 16" = 6 sections.

Insulation is available in appropriate depths/widths and slots in nicely between the studs.

Romex is threaded through various holes drilled through the studs to plug and switch points.

What's not to work? -

• #6995

Zigactly. Pier and beam foundations and stud walls are just so much easier.

Most of Europe uses masonry for their houses. I understand the choice but damn it's hard to change anything without creating a ton of dust.

-

• #6996

Hultafors Talmeter has been my favourite tape measure for a few years, I have 3 of them and a dozen other types, the Talmeter has a few neat features though.

Metric/Metric tape measures for me, I can convert to inches/metric metric/inches on the fly but it's useful to be able to read mm from both sides of the tape.

-

• #6997

(x-posted from AQA)

Anyone know about furniture restoration?

I have a sideboard that has been outside for years (probably 20 or so), next to house under overhang, so rain mostly kept off but exposed to changes in temperature and more than ideal amounts of sunlight/UV. The veneer isn't delaminating anywhere, but on the front feels 'toothy' (rough surface catches fingers/cloth). It's hard to see if it's the veneer or the varnish. On the top you can see a bit more that the grain of the wood has opened up a bit. There's one patch on top that the varnish has just gone. I want to make it smooth and protect the veneer, I'm not really after a proper restoration look.Do I sand/wire wool the tooth down? Strip the varnish? Rehydrate the veneer/varnish somehow to close up the grain?

Does anyone have techniques and/or products to recommend?

Looking online I mostly found how-to's for repairing split/peeling veneer, rather than just the surface.

Photos top to bottom: missing varnish, open grain, what it should look like, toothy.

4 Attachments

-

• #6998

It's a veneer so you need to be careful with any sanding. In the past I've got away with a rotary sander removing all the varnish and applying a wood stain plus a few coats of table top worthy varnish, all water based. You can remove the varnish with paint stripper and wire wool/blades if you are worried about sanding.

Don't expect a perfect finish but you can get a good finish with hand tools and stain/varnish applied with a buffer (folded cotton rags). If you use a power tool start with 80 or 120 grit and go very carefully over the whole piece then come down to 320/400 grit via 180/240/280 to avoid swirls.

It's a light touch job. I've not done it with stripper and wire wool but I know a lot of people do it that way.

You can use a grain filler to cure the open grain. I've avoided it in the past but if you want piano finish then that's the way to do it. You mix it up and pull it across the grain then fine sand it.

Problem is you'll buy enough materials to do 5 cabinets and it costs 5x what you need.

-

• #6999

Button polish FTW!

-

• #7000

Thanks.

I suspect it's pretty thin veneer too as I don't think it's a high quality piece. I'll be going the wire wool route, definitely. And you think to strip the varnish totally? Rather than just get it smooth?Not really looking for a piano finish. Was thinking to use Briwax on it, with shellac sanding sealer where it's bare.

Also do you think Autosol is too harsh to clean up metal details? Look like tarnished bronze, might've been brass. Just y'know, I already have some of that for bike bits...

Aroogah

Aroogah inchpincher

inchpincher MrE

MrE stevo_com

stevo_com Backstop

Backstop Greenbank

Greenbank NotThamesWater

NotThamesWater Dramatic_Hammer

Dramatic_Hammer Soul

Soul withered_preacher

withered_preacher Airhead

Airhead hoefla

hoefla

handtightenonly

handtightenonly @hippy

@hippy

See? Not overkill. But the need for insulation and wiring does preclude the use of 2x4 stud walls.

As a side note - I have an uncle who tried to build a house using only metric back in the late 70s as a way of supporting Carter's push for the metric system. He gave up after 3 weeks.