-

The distance between the bottom of the trough between teeth, and the thread varies between 13.5mm and 14.1mm is that enough to cause this issue?

Yes, it's plenty. Let's give them the benefit of the doubt and say the pitch circle really is a circle but with its centre 0.3mm away from the centre of the bore. If the chain is exactly the right length with the sprocket in it's most rearward position, then half a turn will free up just under 1.2mm of chain to flap about, and if you keep the upper run taut then the lower run can droop by about 15mm if you pull down in the middle of it

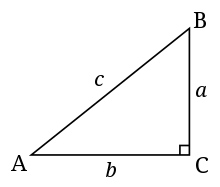

b=200mm

c=200.6mm (the original b plus half the spare chain length)

a²=c²-b²

You are reading a single comment by @cyclotron3k and its replies.

Click here to read the full conversation.

Scilly.Suffolk

Scilly.Suffolk gbj_tester

gbj_tester @cyclotron3k

@cyclotron3k

I noticed my chain is sometimes slack and sometimes pretty much taught, and the slackness seems to be linked to to position of the wheel. I.e. Rotating the wheel 360° makes the chain go from taught to slack and back again.

I don't know why I haven't noticed this earlier but I replaced the cog a few months ago so I assume that's the source of the problem.

I popped the cog off and went at it with some vernier calipers. The distance between the bottom of the trough between teeth, and the thread varies between 13.5mm and 14.1mm is that enough to cause this issue?

It's a 17T 3/32 Soma Fabrications, fwiw.

If it's not the cog, is my hub probably boned?