-

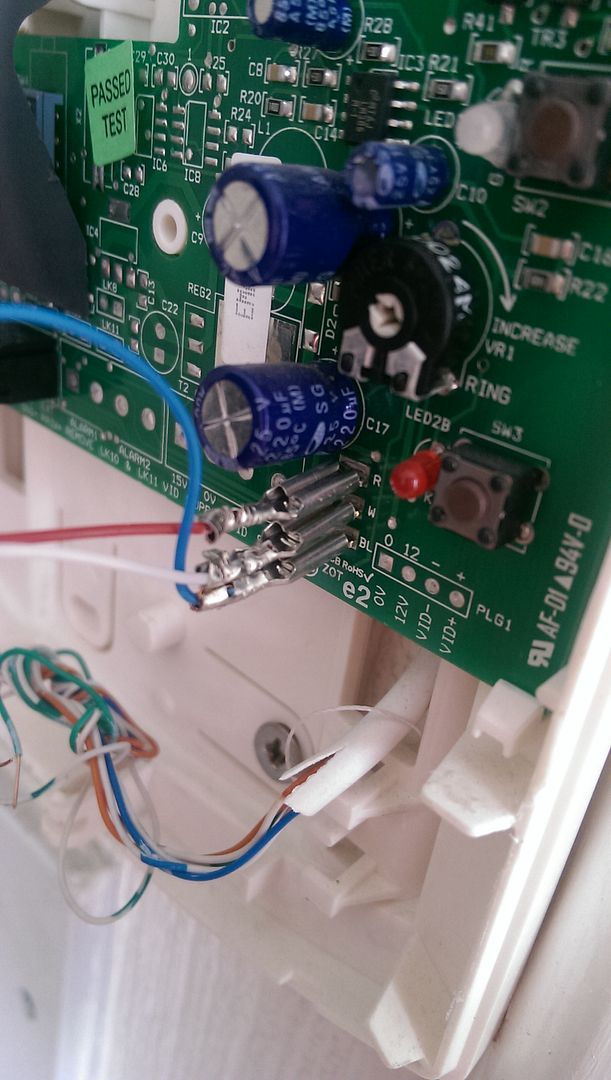

a pic of your spade crimping efforts for teh lolz

/ okaymeme.jpg

i understand why crimping needs to be good and consistent to maximise contact and conduction but i did genuinely find it quite hard to use the crimp tool for this job as the wires are so much smaller than most of the options [/excuses]

re: cradle switch, there isn't the option of depressing and releasing - it is constantly depressed as there is nothing to provide a springback. nothing changes in the procedure if it is lifted. if you look v closely in the last picture i posted (previous post) it does look like, at the top of that little grey unit with the two sets of 3 metal slats poking out underneath the cradle switch, something has been snapped off (i can try and take a better picture if it's not clear).

-

ok lucy, thanks

like you say it appears from the rough top edge of that six pin block that something is missing.

last thing to try - just slip cellotape / insulatro tape around the metal crimps, so as to ensure no crimp to crimp electrical contact

i however think the key is the missing parts from the cradle switch - could be time to shell out £25 for a new unit :(

ioreka

ioreka rive_gauche

rive_gauche

Hi lucy,

2 things:

a pic of your spade crimping efforts for teh lolz.. and to see if there's anything readily amiss

this could be important as if you get a buzz request, lift the handset but the cradle switch doesn't open the pcb will always think it's closed (and no-one is picking up the phone)

also, what do the contacts look like inside of the cradle, damage, spider living inside?